Revolutionary Robotic Arm Technology Takes Manufacturing to the Next Level

By:Admin

In recent years, technological advancements have revolutionized multiple industries, including manufacturing, healthcare, and agriculture. Among these innovations is the development of robotic arms, which have significantly impacted productivity, efficiency, and safety in various operations. One of the leading players in this field is Jaco Robotics.

Jaco Robotics is a cutting-edge robotics company that specializes in designing and manufacturing advanced robotic solutions for a wide range of industries. With a strong focus on innovation, quality, and reliability, the company has established itself as a key player in the global robotics market.

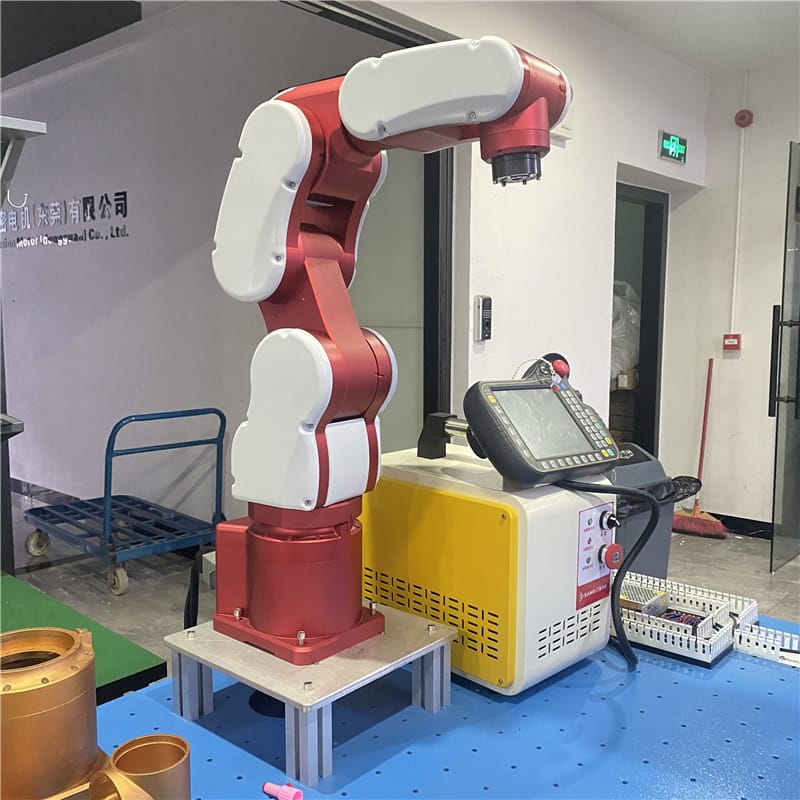

The company's flagship product, the robotic arm, has garnered widespread attention and acclaim for its unparalleled precision, versatility, and performance. Equipped with state-of-the-art technology and advanced capabilities, the robotic arm has become a game-changer in the field of automation.

With its sleek design and advanced features, the robotic arm is capable of performing a diverse array of tasks with utmost precision and efficiency. From assembly line operations in manufacturing facilities to intricate surgical procedures in healthcare settings, the robotic arm has proven to be an invaluable tool for streamlining processes and enhancing productivity.

One of the key strengths of the robotic arm is its adaptability to various environments and applications. Whether it's handling delicate components in a high-tech laboratory or carrying out heavy-duty tasks in a warehouse, the robotic arm can be seamlessly integrated into different settings, offering unparalleled flexibility and versatility.

Furthermore, the robotic arm is equipped with advanced sensors and cutting-edge software that enable it to perform highly complex tasks with remarkable accuracy. Its intuitive interface and user-friendly controls make it easy to operate, allowing technicians and operators to maximize its potential with minimal training.

The integration of artificial intelligence and machine learning algorithms has further enhanced the capabilities of the robotic arm, enabling it to adapt to changing conditions and optimize its performance in real-time. This intelligent technology has proven to be invaluable in improving efficiency and reducing errors in various applications.

In addition to its impressive technical capabilities, the robotic arm is designed with a strong emphasis on safety and reliability. Built with high-quality materials and precision engineering, the robotic arm undergoes rigorous testing and quality assurance to ensure optimal performance and longevity.

The impact of Jaco Robotic Arm has been felt across multiple industries, where it has played a crucial role in driving progress and innovation. In the manufacturing sector, the robotic arm has significantly improved production processes, leading to higher throughput, lower operating costs, and enhanced quality control.

In the healthcare field, the robotic arm has revolutionized surgical procedures, enabling surgeons to perform intricate operations with enhanced precision and dexterity. Its ability to minimize tissue damage and reduce recovery times has made it an indispensable tool in the medical community.

The agricultural industry has also experienced the benefits of the robotic arm, as it has been utilized for tasks such as harvesting, planting, and crop maintenance. Its ability to operate autonomously and handle a wide range of agricultural tasks has improved efficiency and productivity in farming operations.

Looking ahead, Jaco Robotics remains committed to pushing the boundaries of innovation and excellence in robotics. With a strong focus on research and development, the company continues to refine and expand the capabilities of its robotic arm, aiming to further elevate its impact across industries.

In conclusion, Jaco Robotics has set a new standard in the field of automation with its groundbreaking robotic arm. Through its cutting-edge technology, versatility, and precision, the robotic arm has redefined the way tasks are performed across industries, making it a true game-changer in the world of robotics. As technology continues to advance, the potential for the robotic arm to revolutionize more industries and applications is limitless, solidifying its position as a key player in the future of automation.

Company News & Blog

Understanding the Functionality of Servomotors in Servomechanisms

A servomotor is an advanced type of motor that can accurately control the movements of a mechanical system within a servomechanism. This motor is known for its high-level precision and performance, making it a popular choice in various industrial applications.The term servomotor refers to a type of motor that operates based on feedback control. This means that the motor's position, speed, and acceleration are constantly monitored and adjusted to maintain a desired output. Servomotors are commonly used in robotics, CNC machines, and other automated systems that require precise control over movement.One of the most significant advantages of servomotors is their high performance. They are designed to provide precise and fast movements with high accuracy, making them ideal for applications that require high-speed and accurate movements. With the ability to control torque, speed, and position, servomotors are capable of performing complex tasks with ease and efficiency.Another advantage of servomotors is their versatility. They can be designed in various sizes and configurations, making them suitable for a wide range of applications. They are available in DC and AC types, with different feedback mechanisms depending on the specific application requirements.The high performance servomotor is a popular choice in many industries, including medical device manufacturing, aerospace, and automotive. With their ability to deliver high-quality movements, these motors are being used to increase the efficiency and accuracy of various systems. They can also be used in industrial robots to perform complex tasks, such as welding and painting.In conclusion, a servomotor is a highly advanced motor that provides precise and high-speed movements with high accuracy. Its high level of performance makes it an ideal choice for various applications that require precise and efficient movements. With the continued development and advancement in technology, the demand for servomotors is expected to increase in the future, making them a crucial component in the industrial sector.

High-Quality 4-Axis Stepper Motor Controller for Precise Motion Control

The 4 Axis Stepper Motor Controller has been making waves in the industry as a leading solution for precise and efficient motor control. This innovative controller is designed to meet the demands of a wide range of applications, from industrial automation to 3D printing, CNC machining, and more. With its advanced features and robust performance, it has become the go-to choice for businesses and professionals looking for reliable motor control solutions.The 4 Axis Stepper Motor Controller is equipped with cutting-edge technology that sets it apart from traditional motor control systems. Its high-performance stepper motor drivers deliver smooth and accurate motion control, allowing for precise positioning and movement. This level of precision is essential for applications that require intricate and detailed operations, such as CNC machining and 3D printing. Additionally, the controller's advanced microstepping capabilities ensure smooth and quiet operation, reducing vibration and noise for a more efficient and controlled work environment.One of the key features of the 4 Axis Stepper Motor Controller is its user-friendly interface, which makes it easy to set up and operate. The intuitive control panel allows users to adjust motor settings, such as step resolution and acceleration, with ease, eliminating the need for complex programming or extensive technical knowledge. This level of convenience and flexibility is invaluable for businesses that require quick and seamless integration of motor control solutions into their existing workflows.In addition to its advanced features, the 4 Axis Stepper Motor Controller is also known for its reliability and durability. The controller is designed to withstand the rigors of industrial environments, making it a dependable choice for businesses and manufacturers. Its robust construction and high-quality components ensure long-term performance and minimal maintenance, reducing downtime and maximizing productivity.The 4 Axis Stepper Motor Controller is the flagship product of {}, a leading provider of motion control solutions for a wide range of industries. With a strong focus on innovation and quality, {} has earned a reputation for delivering cutting-edge products that meet the demands of modern businesses and professionals. The company's dedication to customer satisfaction and continuous improvement has positioned it as a trusted partner for businesses looking to enhance their motor control capabilities.As businesses and industries continue to evolve, the demand for advanced motor control solutions like the 4 Axis Stepper Motor Controller is expected to grow. With its advanced features, user-friendly interface, and robust performance, this controller is well-equipped to meet the evolving needs of modern businesses and industries. Whether it's precision manufacturing, automated assembly, or intricate 3D printing, the 4 Axis Stepper Motor Controller is poised to become the go-to solution for businesses and professionals looking to elevate their motor control capabilities.In conclusion, the 4 Axis Stepper Motor Controller is a game-changing solution that has set new standards for precision and efficiency in motor control. With its advanced features, user-friendly interface, and robust performance, it has become the top choice for businesses and professionals across a wide range of industries. Backed by the reputation and expertise of {}, this controller is primed to lead the way in the future of motor control solutions.

New Smart Bot Remote Control - Easy and Efficient Control

Introducing the Smart Bot Remote Control: A New Era of Remote Control TechnologyThe world of remote control technology is witnessing a revolution with the introduction of the innovative Smart Bot Remote Control. This cutting-edge device is set to change the way we interact with our electronic gadgets and appliances, offering a level of convenience and control like never before.The Smart Bot Remote Control is the brainchild of a leading technology company that has been at the forefront of innovation and design for over two decades. With a commitment to creating products that enhance the way we live and work, this company has a track record of developing groundbreaking solutions that offer both functionality and style.One of the key features of the Smart Bot Remote Control is its advanced connectivity capabilities. Equipped with state-of-the-art Bluetooth technology, the remote control can seamlessly pair with a wide range of devices, including televisions, set-top boxes, sound systems, and home automation systems. This means that users can now operate all their electronic devices with a single, intuitive remote control, eliminating the need for multiple remotes cluttering up their living space.In addition to its connectivity features, the Smart Bot Remote Control also boasts a user-friendly interface that is designed to simplify the way we interact with our devices. The remote control's sleek and ergonomic design makes it a pleasure to hold and operate, while its intuitive touch screen display provides users with easy access to all of their connected devices. With the Smart Bot Remote Control, controlling your home entertainment system or smart appliances is as easy as a few swipes and taps.Furthermore, the Smart Bot Remote Control is equipped with smart voice recognition technology, allowing users to simply speak commands to control their devices. This feature adds a new level of convenience and accessibility, making it easier for individuals with limited mobility or dexterity to interact with their electronic gadgets.Another standout feature of the Smart Bot Remote Control is its compatibility with virtual assistants such as Amazon Alexa and Google Assistant. By integrating with these popular smart assistants, the remote control becomes a central hub for managing not only entertainment devices, but also smart home systems such as lighting, thermostats, and security cameras. This integration ensures that the Smart Bot Remote Control is not just a remote control, but also a versatile and powerful tool for managing the connected home.The company behind the Smart Bot Remote Control has always been driven by a commitment to innovation, and this latest product is a testament to that dedication. By leveraging the latest advancements in technology and design, they have created a remote control that is not only functional but also intuitive and stylish. The Smart Bot Remote Control is a reflection of the company's ethos of combining cutting-edge technology with user-centric design to create products that enrich the lives of their customers.As the world continues to embrace the Internet of Things (IoT) and smart home technology, the Smart Bot Remote Control is well-positioned to become an essential companion for anyone looking to streamline their control over electronic devices. With its seamless connectivity, user-friendly interface, and integration with virtual assistants, this remote control sets a new standard for convenience and accessibility in the world of smart home technology.In conclusion, the introduction of the Smart Bot Remote Control marks a new era in remote control technology. With its advanced connectivity, user-friendly interface, and compatibility with virtual assistants, this innovative device is set to redefine the way we interact with our electronic gadgets and appliances. Backed by a company with a reputation for innovation and design, the Smart Bot Remote Control is poised to become a game-changer in the world of smart home technology.

Advanced Industrial Robot Arm Technology and Applications in Manufacturing

Industrial Robot Arm Revolutionizing Manufacturing IndustryIn today’s competitive manufacturing industry, businesses are constantly seeking ways to improve efficiency, accuracy, and productivity. One solution that has been gaining traction in recent years is the use of industrial robot arms. These advanced machines are revolutionizing the manufacturing process, driving innovation, and transforming the way products are produced.One company that is at the forefront of this revolution is {Company Name}. With a strong focus on research and development, they have developed a range of industrial robot arms that are helping businesses across the globe streamline their operations and stay ahead of the competition.Industrial robot arms are sophisticated machines that are designed to perform a wide range of tasks with precision and speed. These versatile machines can be programmed to perform complex tasks such as welding, painting, assembly, and packaging, among others. By automating these processes, businesses can reduce the risk of errors, increase production speed, and ultimately improve their bottom line.{Company Name}’s industrial robot arms are equipped with the latest technology, including advanced sensors, high-speed processors, and intuitive programming interfaces. This allows businesses to easily integrate these machines into their existing production lines and customize them to meet their specific needs. The result is a seamless and efficient manufacturing process that delivers high-quality products at a lower cost.One of the key advantages of {Company Name}’s industrial robot arms is their flexibility. These machines can be easily reprogrammed to perform different tasks, making them ideal for businesses that need to adapt to changing market demands. This flexibility also means that businesses can achieve a high level of customization in their products, without the need for expensive and time-consuming retooling.Furthermore, {Company Name} offers comprehensive training and support to ensure that businesses are able to maximize the benefits of their industrial robot arms. This includes on-site training for operators, as well as ongoing technical support to address any issues that may arise. As a result, businesses can rest assured that they are getting the most out of their investment in this advanced technology.The impact of industrial robot arms on the manufacturing industry cannot be overstated. Businesses that have adopted this technology have seen significant improvements in productivity, quality, and profitability. By automating repetitive and labor-intensive tasks, businesses are able to free up their employees to focus on more skilled and creative work, leading to a more satisfied and engaged workforce.In addition, industrial robot arms are also helping businesses to meet the growing demand for sustainable and environmentally friendly products. By reducing waste, improving efficiency, and minimizing the use of resources, these machines are playing a crucial role in helping businesses achieve their sustainability goals.Looking to the future, the potential for industrial robot arms is virtually limitless. As technology continues to advance, we can expect to see even more sophisticated and intelligent machines that are capable of performing an even wider range of tasks. This will open up new possibilities for innovation and creativity in the manufacturing industry, allowing businesses to stay at the forefront of their respective markets.As businesses continue to embrace the benefits of industrial robot arms, it is clear that these machines will play a vital role in shaping the future of manufacturing. By working with a trusted and innovative company like {Company Name}, businesses can take advantage of the latest advancements in this technology and position themselves for long-term success in the global marketplace.

High Performance and Reliable Servo Drives for Easy Integration - Your Guide to Servo Drives 101

Title: High Performance Servo Drives by ADVANCED Motion Controls: A New Standard in Precision and ReliabilityIntroductionADVANCED Motion Controls has recently introduced its groundbreaking line of high-performance servo drives, designed to revolutionize the industrial automation sector. With an unwavering focus on performance, reliability, and ease of integration, these servo drives are set to redefine the standards of precision and efficiency in motion control. Unmatched Performance and PrecisionThe key to the outstanding performance of ADVANCED Motion Controls servo drives lies in their optimally tuned current loops with fast update rates. By incorporating cutting-edge technology, these drives ensure precise control over current output, ensuring optimal motor performance. This, in turn, enhances the overall accuracy, speed, and positioning capabilities of the machines that utilize these servo drives. Another defining feature of these servo drives is their ability to seamlessly integrate velocity and position loops. By precisely matching the demands of each machine, ADVANCED Motion Controls servo drives guarantee unparalleled smoothness and accuracy in motion control. Whether it's complex industrial robotics, CNC machining, or high-speed packaging, these servo drives offer the perfect solution for demanding applications.Reliability at its CoreADVANCED Motion Controls servo drives are meticulously engineered to provide exceptional reliability even in the most challenging industrial environments. With industry-leading components and extensive testing, these servo drives exhibit excellent durability, ensuring uninterrupted operation of critical industrial operations.Moreover, ADVANCED Motion Controls understands the unique requirements of diverse applications. To cater to various system designs, they offer a wide range of servo drive categories, including DC-powered, AC-powered, EtherCAT-enabled, and more. This versatility allows users to choose the most compatible servo drive for their specific application, ensuring seamless integration into the existing infrastructure.Ease of IntegrationADVANCED Motion Controls servo drives are designed with a deep understanding of the need for effortless integration into existing motion control systems. Their servo drive selector tool assists engineers in identifying the most suitable servo drive based on the specific requirements of their projects, simplifying the integration process.Furthermore, these servo drives are compatible with various communication protocols, allowing seamless integration with a wide range of industrial networks. The drives can be easily configured and controlled via intuitive software interfaces, reducing setup time and ensuring a hassle-free installation process.Applications and Future PotentialThe performance and reliability of ADVANCED Motion Controls servo drives make them ideal for a wide range of applications such as industrial robotics, semiconductor manufacturing, aerospace, medical devices, and many more. With their advanced features and precision control capabilities, these servo drives enable businesses to achieve higher productivity, superior product quality, and increased operational efficiency.The future potential of ADVANCED Motion Controls servo drives is vast. As industrial automation continues to evolve, these servo drives will play a crucial role in driving technological advancements. With ongoing research and development, ADVANCED Motion Controls is committed to continually improving its servo drives to meet the increasing demands of modern industries.ConclusionThe introduction of ADVANCED Motion Controls servo drives brings a new era of precision and reliability to the world of motion control. These high-performance drives, with their optimized current loops, integrated velocity and position loops, exceptional reliability, and easy integration capabilities, provide an unparalleled solution for various industrial applications. With the potential to transform industrial processes and maximize productivity, ADVANCED Motion Controls servo drives are set to become the new standard in high-performance motion control technology.

Top 5 Swing Arm Robot Features You Need to Know

Swing Arm Robot is pleased to announce the launch of their new and innovative robotic arm system. The Swing Arm Robot is designed to provide businesses with a versatile and efficient solution for automating various tasks in industries such as manufacturing, packaging, and logistics.With its advanced technology and precision engineering, the Swing Arm Robot is capable of performing a wide range of tasks with speed and accuracy. The robot arm system is equipped with a high-performance servo motor and advanced control system, allowing it to carry out complex movements and actions with ease.One of the key features of the Swing Arm Robot is its flexibility and adaptability. The robot arm can be easily programmed to perform different tasks, making it a valuable asset for businesses looking to streamline their operations and improve productivity. Whether it's picking and placing items on a production line, assembling components, or handling materials in a warehouse, the Swing Arm Robot is up to the task.In addition to its versatility, the Swing Arm Robot is also designed with safety and efficiency in mind. The robot arm is equipped with advanced sensors and safety features to ensure smooth and secure operation in various workplace environments. This makes it an ideal solution for businesses looking to enhance their operational processes while maintaining a safe and secure work environment for their employees.The Swing Arm Robot is also backed by a team of experts who are dedicated to providing exceptional customer support and service. With their extensive knowledge and experience in robotics and automation, the team at Swing Arm Robot is committed to helping businesses integrate and optimize their robotic arm systems for maximum efficiency and effectiveness.In line with their commitment to innovation and excellence, Swing Arm Robot is continuously investing in research and development to further enhance the capabilities of their robotic arm systems. This ensures that businesses can continue to rely on the latest technology and advancements to meet the evolving demands of their industry.The Swing Arm Robot is already making waves in the industry, with several businesses already reaping the benefits of its advanced capabilities. From improved efficiency and productivity to reduced labor costs and enhanced safety, the Swing Arm Robot is proving to be a game-changer for businesses looking to stay ahead in today's competitive market.As the demand for automation and robotics continues to grow, Swing Arm Robot is well-positioned to meet the needs of businesses looking to embrace the future of manufacturing and logistics. With their cutting-edge technology, commitment to excellence, and dedication to customer satisfaction, Swing Arm Robot is truly a leader in the field of robotic arm systems.In conclusion, the Swing Arm Robot is a revolutionary solution for businesses looking to automate their operations and achieve new levels of efficiency and productivity. With its advanced capabilities, safety features, and exceptional customer support, Swing Arm Robot is set to redefine the way businesses approach automation and robotics in the modern era.

Advanced Autonomous Robots in the Industrial Sector

Autonomous Industrial Robots Revolutionizing Manufacturing ProcessesIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking innovative ways to enhance production efficiency, reduce costs, and improve overall operational performance. One company at the forefront of this innovation is {Company Name}, a leading provider of autonomous industrial robots that are revolutionizing manufacturing processes.With years of experience and expertise in robotics and automation, {Company Name} is dedicated to developing cutting-edge solutions that empower manufacturers to streamline their operations and achieve unprecedented levels of productivity. Their autonomous industrial robots are equipped with state-of-the-art technology that enables them to perform a wide range of tasks with precision and reliability, making them an invaluable asset for modern manufacturing facilities.What sets {Company Name}'s autonomous industrial robots apart is their advanced autonomous capabilities, which allow them to operate independently without the need for constant human supervision. This level of autonomy not only reduces the risk of error but also enables manufacturers to allocate their human resources to more complex and strategic tasks, thereby maximizing efficiency and productivity on the factory floor.Furthermore, {Company Name}'s autonomous industrial robots are designed to be easily programmable and adaptable, making them suitable for a variety of applications across different industries. From material handling and assembly to quality control and packaging, these versatile robots can be seamlessly integrated into existing manufacturing processes, providing a flexible and cost-effective solution for businesses of all sizes.One of the key advantages of {Company Name}'s autonomous industrial robots is their ability to operate 24/7, significantly increasing production output and reducing lead times. This round-the-clock capability allows manufacturers to meet tight deadlines and fulfill customer orders in a timely manner, giving them a competitive edge in the market.Moreover, {Company Name} takes great pride in providing comprehensive training and support to ensure that their customers can fully harness the potential of their autonomous industrial robots. By offering customized training programs and ongoing technical assistance, the company aims to empower manufacturers to optimize their operations and achieve long-term success.As the demand for automation continues to grow across the manufacturing sector, {Company Name} remains committed to pushing the boundaries of innovation and driving the industry forward. Their relentless pursuit of excellence and unwavering dedication to customer satisfaction have firmly established them as a trusted partner for businesses looking to capitalize on the benefits of autonomous industrial robots.In conclusion, {Company Name}'s autonomous industrial robots are reshaping the manufacturing landscape by providing a transformative solution that empowers businesses to enhance their operational efficiency, reduce costs, and stay ahead of the competition. Through their advanced technology, versatility, and unwavering commitment to customer success, {Company Name} continues to play a pivotal role in revolutionizing the way modern manufacturing processes are carried out. As the industry evolves, there is no doubt that {Company Name} will remain at the forefront, driving innovation and setting new standards for autonomous industrial robotics.

Affordable CNC Controller: A Cost-Effective Solution for Your Industrial Needs

Low-Cost CNC Controller Revolutionizes Manufacturing IndustryIn today's fast-paced and competitive world, manufacturers are constantly seeking ways to increase efficiency, reduce costs, and improve quality. As a result, the demand for advanced manufacturing technologies has never been greater. One company that has been at the forefront of this trend is {Company Name}, a leading provider of innovative CNC controllers and automation solutions.{Company Name} has recently made waves in the manufacturing industry with the release of its low-cost CNC controller, a groundbreaking product that is set to revolutionize the way manufacturers approach CNC machining. This state-of-the-art controller offers cutting-edge features and capabilities at a fraction of the cost of traditional CNC controllers, making it an extremely attractive option for manufacturers of all sizes.The low-cost CNC controller from {Company Name} is designed to provide high precision and accuracy, seamless integration with a wide range of machining tools, and unparalleled reliability. This means that manufacturers can expect to achieve superior machining results while significantly reducing their operating expenses. With the ability to handle complex machining tasks with ease, this controller is ideal for a wide range of applications, from small-scale production to large-scale manufacturing operations.At the heart of the low-cost CNC controller is a powerful and user-friendly interface that allows operators to program and control the machining process with ease. This intuitive interface is backed by advanced software and hardware components, ensuring that manufacturers can achieve optimal performance and productivity while minimizing downtime. Furthermore, the controller is highly adaptable and can be easily customized to meet the specific needs of different manufacturing processes.One of the key selling points of the low-cost CNC controller from {Company Name} is its ability to deliver exceptional value for money. Unlike traditional CNC controllers that come with a hefty price tag, this controller offers an affordable alternative without sacrificing performance or quality. This means that manufacturers can benefit from state-of-the-art CNC technology without breaking the bank, allowing them to remain competitive in today's challenging marketplace.In addition to its impressive technical capabilities, the low-cost CNC controller is backed by {Company Name}'s renowned customer support and technical expertise. The company's team of experienced engineers and technicians are on hand to provide comprehensive support, maintenance, and training to ensure that customers can maximize the potential of the CNC controller and achieve their manufacturing goals.With the release of the low-cost CNC controller, {Company Name} has once again demonstrated its commitment to driving innovation and excellence in the manufacturing industry. By providing a cost-effective solution that does not compromise on quality or performance, the company is empowering manufacturers to take their production capabilities to new heights.As the manufacturing industry continues to evolve, the low-cost CNC controller from {Company Name} is set to become a game-changer, offering a compelling proposition for manufacturers seeking to enhance their capabilities and remain competitive in the global marketplace. With its combination of advanced features, affordability, and outstanding support, this controller is poised to reshape the way CNC machining is approached, setting a new standard for cost-effective precision manufacturing.In conclusion, {Company Name} remains a driving force in the manufacturing industry, delivering cutting-edge solutions that empower manufacturers to achieve excellence in their production processes. The low-cost CNC controller is a testament to the company's dedication to providing innovative, cost-effective, and high-quality products, and it is sure to have a lasting impact on the industry for years to come.

New CNC Controller for Lathe: A Complete Guide to Upgrading Your Equipment

The world of manufacturing and machining is constantly evolving, and the demand for more precise and efficient machinery is always on the rise. This is where [Company Name] comes in, with their state-of-the-art CNC controller for lathes that is set to revolutionize the industry.[Company Name] has been a leader in the manufacturing and machinery industry for over a decade, specializing in providing high-quality CNC solutions to businesses of all sizes. Their team of experts is dedicated to pushing the boundaries of innovation and technology, and their latest product, the CNC controller for lathes, is a testament to their commitment to excellence.The CNC controller for lathes is designed to offer unparalleled precision and control, allowing operators to create intricate and complex parts with ease. It features a user-friendly interface that makes programming and operation simple and intuitive, reducing the learning curve for new users. The controller also comes equipped with advanced features such as tool path simulation, automatic tool change, and adaptive feed control, all of which contribute to increased efficiency and productivity.One of the key benefits of the CNC controller for lathes is its compatibility with a wide range of lathes, making it a versatile and cost-effective solution for businesses with diverse machining needs. Whether it's for small-scale production or high-volume manufacturing, this controller is capable of meeting the demands of any industry.In addition to its impressive technical capabilities, the CNC controller for lathes is also backed by [Company Name]'s renowned customer support and service. Their team of skilled professionals provides installation, training, and ongoing maintenance to ensure that their clients get the most out of their investment. This level of support is a testament to [Company Name]'s dedication to customer satisfaction and their commitment to building long-lasting partnerships with their clients.The launch of the CNC controller for lathes is a significant milestone for [Company Name], as it further solidifies their position as an industry leader and innovator. Their continuous efforts to push the boundaries of technology and provide cutting-edge solutions underscore their commitment to driving the manufacturing and machining industry forward."We are thrilled to introduce our latest CNC controller for lathes to the market," said [Spokesperson], [Title] at [Company Name]. "We believe that this product will set a new standard for precision and efficiency in the industry, and we are excited to see the positive impact it will have on our clients' businesses."The CNC controller for lathes is now available for purchase, and [Company Name] is confident that it will become an essential tool for businesses looking to enhance their machining capabilities. With its advanced features, user-friendly interface, and exceptional customer support, this controller is set to redefine the way lathes are operated and bring a new level of precision and efficiency to the manufacturing industry.

Discover the Benefits of Collaborative Industrial Robots

Collaborative Industrial Robots are Revolutionizing Manufacturing ProcessesThe world of manufacturing is rapidly evolving, and advancements in technology are at the forefront of this change. One such technological advancement that is revolutionizing the manufacturing sector is the introduction of Collaborative Industrial Robots. These innovative robots are changing the way production processes are carried out, and they are being hailed as the future of manufacturing.One company that is leading the way in the development and implementation of Collaborative Industrial Robots is {}. Founded in 2008, {} has been at the forefront of developing advanced robotics solutions for a wide range of industries. The company has a strong commitment to innovation and has a team of highly skilled engineers and technicians who are dedicated to creating cutting-edge robotic systems.{} has been a pioneer in the field of Collaborative Industrial Robots, and their robots have been widely adopted by companies looking to improve efficiency and productivity in their manufacturing processes. The company's robots are designed to work alongside human workers, performing repetitive tasks with precision and accuracy while allowing human workers to focus on more complex and value-added activities.One of the key advantages of Collaborative Industrial Robots is their ability to work safely alongside human workers. Traditional industrial robots are often housed in cages or other safety barriers to protect workers from accidents. However, Collaborative Industrial Robots are designed to operate in an open environment, without the need for safety barriers. This not only saves valuable floor space in the manufacturing facility but also allows for a more flexible and efficient production process.Another advantage of Collaborative Industrial Robots is their ease of programming and flexibility. These robots are designed to be easy to set up and program, allowing for quick changes in production processes and reducing downtime. This is especially important in today's fast-paced manufacturing environment, where companies need to be able to adapt quickly to changing market demands.The use of Collaborative Industrial Robots has also been shown to improve the overall quality of products. With their precise and consistent performance, these robots can greatly reduce errors and defects in the production process, leading to higher-quality products and increased customer satisfaction.In addition to improving efficiency and productivity, Collaborative Industrial Robots are also leading to significant cost savings for companies. By automating repetitive tasks, these robots can help companies reduce labor costs and improve overall profitability. This is particularly important in industries where labor costs are a significant portion of the total production expenses.The applications of Collaborative Industrial Robots are vast, and they are being used in a wide range of industries, including automotive, electronics, food and beverage, and pharmaceuticals, among others. From assembly and pick-and-place operations to packaging and material handling, these robots are proving to be versatile and valuable assets for manufacturers around the world.As the demand for Collaborative Industrial Robots continues to grow, companies like {} are working tirelessly to further develop and improve these innovative robotic systems. With a strong focus on research and development, they are constantly pushing the boundaries of what is possible with robotics, and are committed to staying at the forefront of the industry.In conclusion, Collaborative Industrial Robots are changing the face of manufacturing. With their ability to work safely alongside human workers, improve efficiency and quality, and reduce costs, these robots are proving to be invaluable assets for companies looking to stay competitive in today's fast-paced market. As technology continues to advance, it is clear that Collaborative Industrial Robots will play a key role in shaping the future of manufacturing.