The Latest Advances in Servo Motor Driver Technology

By:Admin

In today's fast-paced and highly competitive industrial landscape, the demand for precision and efficiency in automation processes is at an all-time high. Now more than ever, companies are seeking advanced technologies to enhance their production capabilities and stay ahead of the curve. One such technology that has been making waves in the industrial automation sector is the servo motor driver.

Servo motor drivers are essential components in industrial automation systems, as they play a crucial role in controlling the speed, position, and torque of the servo motor. These compact yet powerful devices are known for their superior precision, high performance, and reliability, making them indispensable in a wide range of applications such as robotics, CNC machinery, packaging equipment, and more.

The servo motor driver manufactured by {} has garnered widespread acclaim from industry professionals for its cutting-edge features and exceptional performance. With a focus on innovation and quality, {} has established itself as a leading provider of advanced motion control solutions, serving the needs of diverse industries across the globe.

Key features of {}'s servo motor driver include:

1. High-Performance Control Algorithms: {}'s servo motor driver is equipped with advanced control algorithms that ensure smooth and precise motion control, allowing for high-speed operation and optimal accuracy.

2. Built-in Safety Features: The servo motor driver is designed with built-in safety features to protect against overvoltage, overcurrent, and other potential risks, ensuring the safety of both the equipment and the operators.

3. Compact and Modular Design: {}'s servo motor driver is compact in size and offers a modular design, making it easy to integrate into existing automation systems and providing flexibility for future expansion and upgrades.

4. Seamless Communication Interfaces: The servo motor driver supports various communication interfaces such as Ethernet, Modbus, and CANopen, enabling seamless connectivity with PLCs and other control devices for efficient data exchange and system integration.

5. User-Friendly Configuration and Programming: {}'s servo motor driver comes with intuitive software for easy configuration and programming, allowing for quick setup and implementation, and reducing downtime in the production process.

The exceptional performance and reliability of {}'s servo motor driver have made it a go-to choice for industrial automation professionals seeking to optimize their processes and maximize productivity. Furthermore, {}'s commitment to quality, continuous innovation, and customer satisfaction has solidified its reputation as a trusted partner in the industry.

In addition to its cutting-edge products, {} also offers comprehensive technical support, customization services, and training programs to ensure that its customers can fully leverage the capabilities of its servo motor driver and maximize the return on their investment.

As the demand for advanced motion control solutions continues to grow, {} remains at the forefront of the industry, driving innovation and setting new standards for performance and reliability in servo motor driver technology.

With its unwavering dedication to excellence and customer-centric approach, {} is poised to continue making a significant impact on the industrial automation landscape, providing the tools and expertise that companies need to thrive in the increasingly competitive global market.

In conclusion, the servo motor driver technology offered by {} represents a game-changing solution for industrial automation, empowering companies to achieve new levels of precision, efficiency, and productivity. As the industry continues to evolve, {} remains committed to pushing the boundaries of innovation and delivering cutting-edge motion control solutions that shape the future of automation.

Company News & Blog

4-Axis Stepper Motor Driver Card for MACH3 LPT Port Now Available on NVCNC.NET

If you are looking for a reliable and efficient way to control your 4-axis stepper motor, look no further than the MACH3 LPT Port 4 Axis Stepper Motor Driver Card. This versatile and powerful device from Novusun CNC controller is perfect for a wide range of applications, including CNC machining, woodworking, and robotics.At its core, the MACH3 LPT Port 4 Axis Stepper Motor Driver Card is designed to provide precise and accurate control over your stepper motor system. With its advanced microstepping technology, this card can deliver smooth and seamless motion control for even the most intricate and demanding tasks.One of the key benefits of this stepper motor driver card is its compatibility with a wide range of CNC controllers and software platforms. Whether you are using a Novusun CNC controller, a Nvum CNC controller, or any other popular CNC software program, the MACH3 LPT Port 4 Axis Stepper Motor Driver Card can seamlessly integrate with your existing setup and provide reliable, consistent performance.Perhaps one of the most impressive features of this stepper motor driver card is its ability to handle multiple motor axes simultaneously. With support for up to 4 axes of control, this card can handle even the most complex and demanding machining tasks with ease.Of course, no stepper motor driver card would be complete without a robust and user-friendly control interface. The MACH3 LPT Port 4 Axis Stepper Motor Driver Card includes an intuitive and easy-to-use interface that allows you to fine-tune your motor control settings and monitor your system's performance in real-time.To sum it up, the MACH3 LPT Port 4 Axis Stepper Motor Driver Card from Novusun CNC controller is a versatile and reliable solution for controlling your stepper motor system. With advanced microstepping technology, multi-axis support, and a user-friendly interface, this card is a must-have for any serious CNC hobbyist or professional.

Ultimate Guide to High Performance Servo Drives for Industrial Applications

High Performance Servo Drive Revolutionizing Industrial AutomationIn the rapidly evolving field of industrial automation, one company is leading the way with their groundbreaking high-performance servo drive. This innovative technology is set to revolutionize the way industries operate, offering unprecedented levels of precision, speed, and efficiency. With a proven track record of delivering cutting-edge solutions, {Company Name} has established itself as a global leader in the field of motion control and automation.{Company Name} is a renowned provider of advanced motion control products and solutions, serving a wide range of industries including robotics, packaging, automotive, and aerospace. With a strong focus on innovation and customer satisfaction, the company has consistently delivered top-quality products that have set new benchmarks in the industry.The high-performance servo drive developed by {Company Name} is a game-changer in the world of industrial automation. Featuring state-of-the-art technology and advanced control algorithms, this servo drive offers unparalleled levels of precision and performance. It is capable of handling high-speed and high-precision applications with ease, making it the go-to choice for industries that demand nothing but the best.One of the key factors that sets {Company Name}'s servo drive apart from the competition is its advanced communication capabilities. With support for various industrial communication protocols, the servo drive seamlessly integrates into existing automation systems, providing a seamless and efficient solution for industries looking to upgrade their motion control systems.Another standout feature of the high-performance servo drive is its robust and reliable design. Built to withstand the rigors of industrial environments, this servo drive is engineered to deliver consistent performance even in the most demanding applications. With a focus on durability and longevity, {Company Name} has ensured that their servo drive is a long-term investment for companies looking to improve their automation processes.The impact of {Company Name}'s high-performance servo drive on industrial automation is already being felt across various industries. From improving production efficiency to enabling new capabilities in robotics and automation, this innovative technology is helping companies stay ahead of the curve in a rapidly evolving market.In addition to their cutting-edge products, {Company Name} is also known for their exceptional customer support and service. With a team of highly skilled engineers and technicians, the company offers comprehensive support to help customers integrate and optimize their motion control systems. This commitment to customer satisfaction has played a crucial role in {Company Name}'s success and has earned them a reputation as a trusted partner in the industry.Looking ahead, {Company Name} is poised to continue leading the way in the field of industrial automation with their innovative solutions and unwavering commitment to excellence. With a focus on research and development, the company is constantly pushing the boundaries of what is possible in motion control and automation, ensuring that their customers have access to the latest and most advanced technology available.As industries continue to embrace automation and seek ways to improve their processes, {Company Name}'s high-performance servo drive is set to play a pivotal role in shaping the future of industrial automation. With its unmatched performance, reliability, and support, this innovative technology is well-positioned to become the industry standard for motion control in the years to come.In conclusion, {Company Name}'s high-performance servo drive is a testament to their commitment to innovation and excellence in industrial automation. With its advanced technology, robust design, and exceptional support, this servo drive is setting new standards for performance and reliability in motion control. As industries look for ways to optimize their processes and stay ahead of the competition, {Company Name} remains a trusted partner in providing the tools and solutions they need to succeed.

Affordable CNC Controller Options for Your Business

Low Cost CNC Controller Revolutionizes Manufacturing IndustryIn today’s fast-paced and highly competitive manufacturing industry, efficiency and precision are essential for success. The use of Computer Numerical Control (CNC) machines has revolutionized the way products are manufactured by allowing for automated control of machining tools such as drills, lathes, and mills. The use of CNC machines has become a standard practice in the industry, but the high cost of traditional CNC controllers has often been a barrier for small and medium-sized businesses. However, with the introduction of the low-cost CNC controller by {company}, businesses of all sizes can now benefit from this cutting-edge technology.{Company} is a leading provider of industrial automation solutions, specializing in the development and manufacturing of CNC controllers and other machinery control systems. With a strong focus on innovation and customer satisfaction, {company} has been at the forefront of revolutionizing the manufacturing industry and has made significant contributions to the advancement of CNC technology. The launch of their low-cost CNC controller is the latest example of their commitment to making advanced manufacturing technology accessible to businesses of all sizes.The low-cost CNC controller developed by {company} offers the same level of precision and performance as traditional controllers, but at a fraction of the cost. This makes it an ideal solution for small and medium-sized businesses that are looking to improve their production processes without breaking the bank. In addition to the affordability, the controller is also user-friendly, making it easy for operators to learn and utilize the technology effectively.One of the key features of the low-cost CNC controller is its compatibility with a wide range of CNC machines, making it a versatile solution for manufacturers in various industries. Whether a business is involved in metalworking, woodworking, or 3D printing, this controller can be seamlessly integrated into existing production systems, allowing for a smooth transition to automated machining processes.Furthermore, the low-cost CNC controller comes with a comprehensive support package from {company}, including training and technical assistance. This ensures that businesses can make the most of their investment and maximize the benefits of CNC technology. With the support of {company}’s team of experts, businesses can confidently adopt the new technology and enhance their manufacturing capabilities.The introduction of the low-cost CNC controller by {company} has garnered attention from the manufacturing industry, with many businesses expressing interest in adopting the technology. Small and medium-sized businesses, in particular, have welcomed this new solution as it offers an affordable way to improve their production processes and compete with larger manufacturers. As a result, {company} has seen an increase in demand for their low-cost CNC controller, with businesses eager to take advantage of this game-changing technology.In conclusion, the low-cost CNC controller developed by {company} is set to revolutionize the manufacturing industry by making advanced machining technology accessible to businesses of all sizes. With its affordability, versatility, and comprehensive support package, this controller has the potential to empower small and medium-sized businesses to enhance their production processes and stay competitive in the market. As a leading provider of industrial automation solutions, {company} continues to drive innovation in the industry and set new standards for CNC technology.

Ultimate Guide to Ac Servo Motor Controller: Everything You Need to Know

[Company Name] introduces new cutting-edge AC Servo Motor Controller[City, Date] - [Company Name], a leading provider of innovative automation solutions, has announced the launch of its latest product, the AC Servo Motor Controller. This groundbreaking controller offers unparalleled precision, reliability, and performance for a wide range of industrial applications.The AC Servo Motor Controller is designed to meet the demanding requirements of modern automation systems. It features advanced control algorithms and high-speed processing capabilities, ensuring smooth and accurate motor control in various operating conditions. With its compact and robust design, the controller is suitable for use in diverse industries, including manufacturing, robotics, packaging, and material handling."We are thrilled to introduce our new AC Servo Motor Controller to the market," said [Spokesperson Name], CEO of [Company Name]. "This product embodies our commitment to delivering cutting-edge automation solutions that empower our customers to achieve new levels of efficiency and productivity."One of the key features of the AC Servo Motor Controller is its seamless integration with [Company Name]'s comprehensive range of motion control products. This allows for easy and efficient setup and commissioning, as well as seamless interoperability with existing automation systems. The controller also offers a wide range of communication interfaces, including Ethernet, USB, and CAN, enabling seamless integration with other devices and control systems.In addition to its advanced technical capabilities, the AC Servo Motor Controller is supported by [Company Name]'s extensive network of service and support professionals. Customers can rely on prompt and knowledgeable assistance, including technical support, training, and maintenance services, ensuring maximum uptime and performance of their automation systems.[Company Name] has a proven track record of delivering innovative automation solutions to a global customer base. With a strong focus on research and development, the company continually pushes the boundaries of technological innovation, enabling its customers to stay ahead in an increasingly competitive market.The introduction of the AC Servo Motor Controller is expected to further strengthen [Company Name]'s position as a leading provider of automation solutions. The company's commitment to quality, reliability, and customer satisfaction sets it apart in the industry and has earned it the trust of numerous businesses worldwide."We are confident that the AC Servo Motor Controller will be a game-changer for many of our customers," [Spokesperson Name] added. "Its advanced features and robust design make it an ideal choice for a wide range of applications, and we look forward to seeing the positive impact it will have in the field of industrial automation."As [Company Name] continues to expand its product portfolio and reach new markets, the company is poised to remain at the forefront of the automation industry. Through its dedication to innovation and customer-centric approach, [Company Name] is set to deliver even more groundbreaking solutions in the years to come.For more information about the AC Servo Motor Controller and [Company Name]'s complete range of automation solutions, please visit [Company Website].

Top CNC Drive Systems for Improved Efficiency and Performance

CNC Drive Systems Revolutionizing Manufacturing IndustryIn today's fast-paced and technologically advanced world, the manufacturing industry is constantly evolving to meet the demands of consumers. One of the key drivers of this evolution is the development and implementation of CNC drive systems, which have revolutionized the way many companies produce goods in a wide range of industries.A CNC drive system is a sophisticated piece of equipment that enables precision control of machinery and tools in a manufacturing setting. By using computer numerical control (CNC) technology, these systems allow for highly accurate and efficient production processes, leading to improved quality, increased productivity, and reduced waste.One company at the forefront of this technology is a leading provider of CNC drive systems, offering a comprehensive range of solutions to meet the diverse needs of manufacturers across various industries. With a strong focus on innovation, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses looking to enhance their manufacturing capabilities.The company's CNC drive systems are designed to integrate seamlessly with a wide range of machinery and equipment, allowing for precise control and customization of manufacturing processes. Whether it's milling, turning, grinding, or any other type of machining operation, their systems provide the flexibility and accuracy needed to optimize production and achieve consistently high-quality results.In addition to their advanced technology, the company also offers comprehensive support and service to ensure that their customers get the most out of their CNC drive systems. From installation and training to ongoing maintenance and technical assistance, their team of experts is dedicated to helping manufacturers maximize the value of their investment and stay ahead of the competition.The benefits of implementing CNC drive systems are clear, with many companies experiencing significant improvements in their manufacturing operations after adopting this technology. By automating and optimizing key processes, businesses can reduce production costs, minimize errors, and increase throughput, ultimately leading to higher profitability and a competitive edge in the market.Furthermore, the precision and consistency enabled by CNC drive systems also open up new opportunities for manufacturers to expand their product offerings and enter new markets. With the ability to produce complex parts and components with tight tolerances, businesses can take on more challenging projects and meet the evolving demands of their customers.As the manufacturing industry continues to evolve, it's clear that CNC drive systems will play a crucial role in shaping the future of production. By harnessing the power of advanced technology and automation, businesses can achieve new levels of efficiency, reliability, and quality, ultimately driving growth and success in a rapidly changing global market.In conclusion, the ongoing development and adoption of CNC drive systems represent a significant step forward for the manufacturing industry, empowering businesses to stay competitive and meet the demands of a modern, dynamic marketplace. With the support of leading providers like the aforementioned company, manufacturers have access to the tools and expertise they need to thrive in an increasingly complex and demanding business environment.

The Latest Advances in Servo Motor Driver Technology

Servo Motor Driver Technology: Revolutionizing Industrial AutomationIn today's fast-paced and highly competitive industrial landscape, the demand for precision and efficiency in automation processes is at an all-time high. Now more than ever, companies are seeking advanced technologies to enhance their production capabilities and stay ahead of the curve. One such technology that has been making waves in the industrial automation sector is the servo motor driver.Servo motor drivers are essential components in industrial automation systems, as they play a crucial role in controlling the speed, position, and torque of the servo motor. These compact yet powerful devices are known for their superior precision, high performance, and reliability, making them indispensable in a wide range of applications such as robotics, CNC machinery, packaging equipment, and more.The servo motor driver manufactured by {} has garnered widespread acclaim from industry professionals for its cutting-edge features and exceptional performance. With a focus on innovation and quality, {} has established itself as a leading provider of advanced motion control solutions, serving the needs of diverse industries across the globe.Key features of {}'s servo motor driver include:1. High-Performance Control Algorithms: {}'s servo motor driver is equipped with advanced control algorithms that ensure smooth and precise motion control, allowing for high-speed operation and optimal accuracy.2. Built-in Safety Features: The servo motor driver is designed with built-in safety features to protect against overvoltage, overcurrent, and other potential risks, ensuring the safety of both the equipment and the operators.3. Compact and Modular Design: {}'s servo motor driver is compact in size and offers a modular design, making it easy to integrate into existing automation systems and providing flexibility for future expansion and upgrades.4. Seamless Communication Interfaces: The servo motor driver supports various communication interfaces such as Ethernet, Modbus, and CANopen, enabling seamless connectivity with PLCs and other control devices for efficient data exchange and system integration.5. User-Friendly Configuration and Programming: {}'s servo motor driver comes with intuitive software for easy configuration and programming, allowing for quick setup and implementation, and reducing downtime in the production process.The exceptional performance and reliability of {}'s servo motor driver have made it a go-to choice for industrial automation professionals seeking to optimize their processes and maximize productivity. Furthermore, {}'s commitment to quality, continuous innovation, and customer satisfaction has solidified its reputation as a trusted partner in the industry.In addition to its cutting-edge products, {} also offers comprehensive technical support, customization services, and training programs to ensure that its customers can fully leverage the capabilities of its servo motor driver and maximize the return on their investment.As the demand for advanced motion control solutions continues to grow, {} remains at the forefront of the industry, driving innovation and setting new standards for performance and reliability in servo motor driver technology.With its unwavering dedication to excellence and customer-centric approach, {} is poised to continue making a significant impact on the industrial automation landscape, providing the tools and expertise that companies need to thrive in the increasingly competitive global market.In conclusion, the servo motor driver technology offered by {} represents a game-changing solution for industrial automation, empowering companies to achieve new levels of precision, efficiency, and productivity. As the industry continues to evolve, {} remains committed to pushing the boundaries of innovation and delivering cutting-edge motion control solutions that shape the future of automation.

Cutting-Edge CNC Controller Technology Revolutionizes Industry

Title: Revolutionary CNC Controller Improves Precision and Efficiency in Manufacturing ProcessesIntroductionWith the rapid advancement of technology, the manufacturing industry has witnessed a substantial transformation in recent years. One critical element that has played a pivotal role in this evolution is the development of sophisticated Computer Numerical Control (CNC) machines. Szgh, a leading innovator in the field of CNC technology, has made great strides in revolutionizing the industry with its state-of-the-art CNC Controller. This cutting-edge product is designed to enhance precision and efficiency in various manufacturing processes, empowering businesses to stay ahead of the competition.Enhancing Precision and AccuracyThe Szgh CNC Controller is renowned for its exceptional precision and accuracy, providing manufacturers unmatched control over their machining operations. Equipped with advanced algorithms and powerful computing capabilities, the controller ensures precise positioning, high-speed operation, and improved surface finish quality. Manufacturing defects resulting from human error are significantly reduced, leading to increased production yields and cost savings. With its intelligent control system, the Szgh CNC Controller eliminates dimensional variations often found in manual machining, resulting in products that conform perfectly to design specifications.Optimizing Efficiency and ProductivityIn addition to precision, the Szgh CNC Controller is designed to optimize efficiency and productivity throughout the manufacturing process. The controller's user-friendly interface allows operators to easily program and monitor machining operations in real-time, reducing setup time and minimizing downtime. The seamless integration between the CNC system and the machine tools enables quick tool changes, resulting in faster turnaround times and boosting overall productivity. With high-speed processing capabilities, the controller ensures rapid execution of complex machining tasks, contributing to enhanced production throughput.Advanced Features and CapabilitiesThe Szgh CNC Controller boasts a range of advanced features and capabilities that set it apart from traditional CNC systems. Its adaptive control technology allows for automatic adjustments based on real-time feedback, ensuring optimal cutting conditions and preventing tool wear. The controller incorporates intelligent tool path planning algorithms, minimizing unnecessary movements and reducing cycle times. Furthermore, the advanced diagnostics and monitoring functions enable operators to identify any issues promptly, preventing production bottlenecks and costly errors.Industry Applications and VersatilityThe Szgh CNC Controller finds applications across various industries, including automotive, aerospace, electronics, and medical device manufacturing. Its versatility and compatibility with a wide range of CNC machines make it an ideal solution for diverse machining tasks. The controller seamlessly integrates with various peripheral devices, such as robotic arms and vision systems, facilitating automation and enhancing operational flexibility. Furthermore, its modular architecture allows for easy upgrades and expansions, ensuring compatibility with future advancements in CNC technology.Customer-Centric Approach and Technical SupportSzgh has built a strong reputation for its customer-centric approach, focusing on providing comprehensive technical support and training to its clients. The company's team of highly skilled engineers offers prompt assistance in installation, operation, and maintenance, ensuring smooth integration of the CNC Controller into each customer's unique manufacturing environment. Regular software updates and firmware improvements guarantee that customers benefit from the latest advancements and technological enhancements, keeping their operations at the forefront of the industry.ConclusionSzgh's CNC Controller represents a groundbreaking advancement in CNC technology, revolutionizing the manufacturing industry by enhancing precision, accuracy, efficiency, and productivity. With its user-friendly interface, advanced features, and compatibility across industries, the CNC Controller sets a new standard for machining operations. As the industry continues to evolve, Szgh remains committed to pushing boundaries and developing innovative solutions that redefine manufacturing productivity and quality.

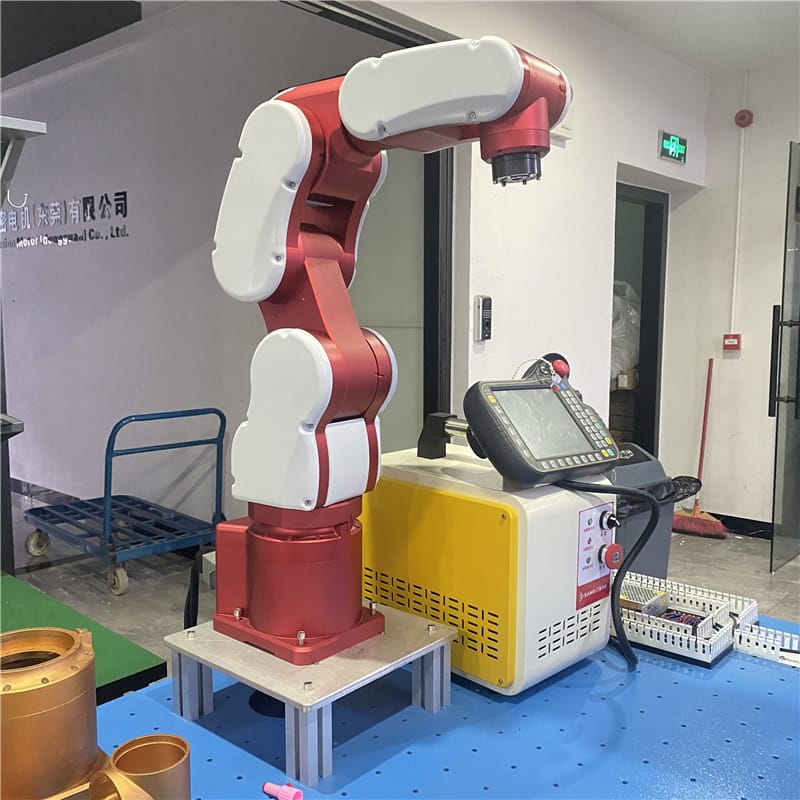

Cutting-Edge Robotic Arm Factory Revolutionizes Manufacturing Process

Robotic Arm Factory, a leading manufacturer of advanced robotic arm systems, has recently made a significant technological breakthrough that is set to revolutionize the industry. The company, known for its innovative approach to automation and robotics, has developed a new generation of robotic arms that are not only faster and more agile, but also more precise and adaptable than ever before.With a strong focus on research and development, Robotic Arm Factory has been able to push the boundaries of what is possible in the field of robotics. Their latest creation, the [product name], represents a leap forward in robotic arm technology, offering unparalleled levels of performance and flexibility.One of the key features of the [product name] is its advanced motion control system, which allows for incredibly smooth and precise movements. This level of precision makes the robotic arm ideal for a wide range of applications, from manufacturing and assembly to pick-and-place tasks and even delicate surgical procedures.In addition to its exceptional precision, the [product name] is also faster and more efficient than previous models. Thanks to its state-of-the-art design and construction, the robotic arm is able to achieve higher speeds and greater acceleration, resulting in a significant increase in productivity for any task it is assigned to.Another standout feature of the [product name] is its adaptability. The robotic arm is equipped with a range of sensors and actuators that allow it to quickly and accurately respond to changes in its environment. This means that the arm is able to handle a wide variety of tasks without the need for reprogramming or recalibration, making it a highly versatile and cost-effective solution for businesses in any industry.The development of the [product name] is the result of years of dedicated research and collaboration. Robotic Arm Factory has assembled a world-class team of engineers and technicians who are committed to pushing the boundaries of robotics and automation. Through a combination of cutting-edge technologies and a deep understanding of the needs of their customers, the company has been able to create a robotic arm that sets a new standard for performance and reliability.The [product name] is just the latest in a long line of groundbreaking innovations from Robotic Arm Factory. The company has a proven track record of delivering high-quality, reliable robotic arm systems to businesses around the world, and the [product name] is set to further solidify their position as a leader in the industry."We are incredibly proud of what we have achieved with the [product name]," said [company spokesperson]. "This robotic arm represents the culmination of years of hard work and dedication from our team, and we are confident that it will make a significant impact on the industry. We believe that the [product name] will help businesses to achieve new levels of productivity and efficiency, and we are excited to see the ways in which it will be used in the real world."As businesses continue to seek out ways to improve their operations and stay ahead of the competition, the [product name] from Robotic Arm Factory is set to become an essential tool for a wide range of industries. With its exceptional precision, speed, and adaptability, the robotic arm is poised to revolutionize the way that tasks are carried out, offering a level of performance that was previously unattainable.Whether it's in a factory, a warehouse, a hospital, or any other setting, the [product name] is set to make a real difference to businesses of all sizes. It is a testament to the power of innovation and engineering, and a clear sign that the future of robotics is brighter than ever.

Understanding the Benefits of Electric Drive Motors

Electric Drive Motor Revolutionizing the Automotive IndustryThe automotive industry has seen immense changes over the years, from the introduction of electric vehicles to the development of autonomous driving technology. One of the key components driving this transformation is the electric drive motor. These motors have become synonymous with efficient, eco-friendly transportation, and have been instrumental in reducing carbon emissions and promoting sustainability in the automotive sector.Electric drive motors have revolutionized the way vehicles are powered and are now being used in a wide range of applications, from passenger cars to commercial vehicles and even heavy-duty trucks. One company that has been at the forefront of this innovation is [Company Name]. They have been leading the way in developing cutting-edge electric drive motors that are not only powerful and reliable but also environmentally friendly.[Company Name] has a long history of producing high-quality electric drive motors, and their expertise in this area sets them apart from their competitors. Their commitment to innovation and sustainability has made them a key player in the electric vehicle industry.With a strong focus on research and development, [Company Name] has been able to develop electric drive motors that are more efficient and powerful than ever before. Their motors are designed to deliver exceptional performance while also reducing energy consumption and minimizing environmental impact. This has made them a popular choice among automotive manufacturers looking to produce cleaner and greener vehicles.In addition to their electric drive motors, [Company Name] also offers a range of other products and services that support the electrification of the automotive industry. Their expertise in battery technology, power electronics, and vehicle integration has allowed them to provide comprehensive solutions for electric vehicle manufacturers, helping them to bring their products to market quickly and efficiently.One of the key advantages of [Company Name]'s electric drive motors is their versatility. They can be adapted to suit a wide range of vehicle types and sizes, making them an ideal choice for manufacturers looking to electrify their entire fleet. This flexibility has made [Company Name] a trusted partner for many automotive companies looking to transition to electric vehicles.The demand for electric vehicles is on the rise, and [Company Name] is well-positioned to meet this growing need. Their state-of-the-art manufacturing facilities and extensive research capabilities enable them to produce electric drive motors at scale, ensuring that they can meet the needs of their customers around the world.Moreover, [Company Name] also offers a comprehensive range of support services for their electric drive motors, including installation, maintenance, and repair. This ensures that their customers can rely on their products for years to come, knowing that they have the full support of [Company Name] behind them.In conclusion, electric drive motors are playing a pivotal role in revolutionizing the automotive industry, and [Company Name] is at the forefront of this transformation. Their commitment to innovation, sustainability, and customer satisfaction has made them a trusted partner for automotive manufacturers looking to embrace the future of transportation. With their cutting-edge technology and comprehensive range of products and services, [Company Name] is well-positioned to continue leading the way in the electrification of vehicles, driving the automotive industry toward a more sustainable and eco-friendly future.