Top Autonomous Industrial Robots in 2022: A Complete Guide

By:Admin

In today's rapidly advancing industrial landscape, the use of autonomous industrial robots has become increasingly prevalent in manufacturing facilities around the world. These sophisticated machines are revolutionizing the way products are made, offering unparalleled efficiency, precision, and flexibility to manufacturers.

One company at the forefront of this innovation is {}. Specializing in the development and implementation of cutting-edge industrial automation solutions, {} has been instrumental in catalyzing the widespread adoption of autonomous robots across various industries. With a strong commitment to pushing the boundaries of technology, {} has consistently delivered state-of-the-art robotic systems that have redefined manufacturing standards.

Enabled with advanced artificial intelligence and machine learning capabilities, autonomous industrial robots have the capacity to perform complex tasks with minimal human intervention. From assembly and packaging to material handling and quality control, these robots are adept at executing a diverse range of operations with unmatched speed and accuracy. Moreover, their ability to adapt to changing production requirements makes them indispensable assets in the modern manufacturing ecosystem.

One of the key advantages of deploying autonomous industrial robots is their potential to significantly enhance overall operational efficiency. By streamlining production processes and reducing cycle times, these robots facilitate substantial cost savings and productivity gains for manufacturers. Furthermore, their ability to operate continuously for extended periods without fatigue or error ensures consistent output and high product quality.

Another compelling aspect of autonomous industrial robots is their role in improving workplace safety. In hazardous or strenuous working environments, these robots can take on tasks that pose risks to human workers, thus minimizing the potential for accidents and injuries. This not only prioritizes the well-being of employees but also contributes to a more sustainable and responsible manufacturing practice.

In addition to their operational benefits, autonomous industrial robots also offer manufacturers the flexibility to adapt to evolving market demands. Their agile nature enables swift reconfiguration for different production setups, ultimately empowering companies to respond agilely to changing consumer preferences and market trends. This agility is paramount in today's competitive landscape, where adaptability and speed to market are critical for success.

Recognizing the transformative potential of autonomous industrial robots, {} has continually invested in research and development to further enhance the capabilities of these machines. By leveraging the latest advancements in robotics, artificial intelligence, and automation, the company has been able to consistently deliver groundbreaking solutions that empower manufacturers to stay ahead of the curve.

Moreover, {} takes a comprehensive approach to integrating autonomous robots into manufacturing operations. From initial consultation and system design to installation and ongoing support, the company works closely with its clients to ensure seamless integration and optimal performance of these cutting-edge robotics solutions. This commitment to customer satisfaction has earned {} a reputation for excellence in the field of industrial automation.

Looking ahead, the future of manufacturing undoubtedly revolves around the increasing integration of autonomous industrial robots. As technology continues to advance, these robots will play an even more pivotal role in driving efficiency, innovation, and competitiveness in the global manufacturing landscape. With {} leading the charge in pioneering next-generation robotics solutions, the industry is poised for a paradigm shift that will redefine the way products are made.

Company News & Blog

High-powered 24v Electric Motor for Efficient Performance

A leading manufacturer in the electric motor industry has recently announced the release of their innovative 24v electric motor. This new product is designed to offer high performance and efficiency, catering to the growing demand for electric motors in various industries.With a focus on delivering cutting-edge technology and top-notch quality, the company has been at the forefront of the electric motor market for several years. Their commitment to research and development has enabled them to stay ahead of the competition and constantly introduce new, advanced products to the market.The 24v electric motor is a testament to the company's dedication to providing reliable and high-performing solutions for their customers. With a focus on performance, durability, and energy efficiency, this new motor is expected to make waves in the industry and meet the needs of a wide range of applications.One of the key features of the 24v electric motor is its compact design, which allows for easy integration into various systems and equipment. This makes it an ideal choice for manufacturers and businesses looking to enhance the performance of their products while reducing energy consumption.In addition to its compact size, the motor also boasts a high power output, making it suitable for demanding applications across different industries. Whether it's used in automotive, industrial, or commercial settings, this electric motor is designed to deliver consistent, reliable performance.The company's commitment to quality is evident in the rigorous testing and certification processes that all their products undergo. The 24v electric motor is no exception, as it has been thoroughly tested to ensure compliance with industry standards and regulations, giving customers peace of mind knowing they are investing in a high-quality, reliable product.Furthermore, the company's dedication to sustainability is reflected in the energy efficiency of the 24v electric motor. By minimizing energy consumption and reducing carbon emissions, this motor aligns with the company's environmentally conscious approach to manufacturing and product development.The release of the 24v electric motor comes at a time when industries are increasingly transitioning toward electrification and sustainable solutions. With the global push for reducing carbon footprints and embracing clean energy, electric motors have become a crucial component in various applications, ranging from electric vehicles to industrial machinery.The company's extensive experience and expertise in the electric motor industry positions them as a trusted partner for businesses seeking reliable, high-quality solutions. With a strong focus on customer satisfaction and continuous improvement, they are well-equipped to meet the diverse needs of their clients and provide tailored solutions to address specific challenges.As the demand for electric motors continues to grow, the introduction of the 24v electric motor further solidifies the company's position as an industry leader. With a proven track record of delivering top-of-the-line products and exceptional customer service, they are poised to make a significant impact with this latest addition to their product lineup.In conclusion, the release of the 24v electric motor underscores the company's commitment to innovation, quality, and sustainability. As industries continue to embrace electric solutions, this new motor is set to play a pivotal role in driving efficiency and performance across various applications. With its advanced features and high-performance capabilities, it is poised to set a new standard for electric motors in the industry.

New 6 Axis Robot: Compact and Versatile Automation Technology

Small 6 Axis Robot Revolutionizes Industrial AutomationIndustrial automation has taken a giant leap forward with the launch of the Small 6 Axis Robot by [company name]. This compact and powerful robotic arm is set to revolutionize manufacturing processes across a wide range of industries.The Small 6 Axis Robot is equipped with six axes of movement, giving it the flexibility to handle complex tasks with precision and efficiency. Its compact design allows it to operate in tight spaces, making it ideal for small-scale manufacturing environments. The robot is also capable of carrying a payload of up to 5 kilograms, making it a versatile tool for handling a variety of materials and components.One of the key features of the Small 6 Axis Robot is its advanced motion control system. This system allows the robot to move with incredible speed and accuracy, making it the perfect choice for high-speed assembly and pick-and-place applications. With a repeatability of 0.02mm, the robot can consistently perform tasks with a high level of precision, ensuring a high-quality end product.In addition to its impressive performance capabilities, the Small 6 Axis Robot is also incredibly user-friendly. It can be easily programmed and reconfigured to suit specific manufacturing requirements, thanks to its intuitive software interface. This allows businesses to quickly adapt the robot to new tasks and production processes, maximizing its potential within a manufacturing facility.[Company name] has a long-standing reputation for delivering high-quality automation solutions to a wide range of industries. With a focus on innovation and customer satisfaction, the company has become a trusted partner for businesses looking to enhance their manufacturing capabilities. The Small 6 Axis Robot is the latest addition to [company name]'s portfolio of cutting-edge automation solutions, and it is set to become a game-changer for businesses seeking to improve their production processes.The Small 6 Axis Robot has already garnered significant interest from businesses across various industries, thanks to its impressive performance and versatility. Its ability to streamline manufacturing processes and improve productivity has made it a standout choice for businesses looking to stay ahead of the competition.The capabilities of the Small 6 Axis Robot extend beyond traditional manufacturing applications. Its compact size and advanced motion control system make it well-suited for use in research and development, as well as in educational settings. This versatility opens up new possibilities for businesses and institutions looking to leverage the power of robotics in their operations.With the launch of the Small 6 Axis Robot, [company name] is poised to set new standards in industrial automation. By combining advanced technology with user-friendly design, the company has delivered a solution that meets the evolving needs of modern manufacturing. Businesses looking to optimize their production processes and stay at the forefront of innovation will find the Small 6 Axis Robot to be an invaluable asset.As the demand for automation continues to grow, the Small 6 Axis Robot is set to play a pivotal role in shaping the future of manufacturing. Its ability to improve productivity, enhance quality, and adapt to changing production requirements makes it a must-have tool for businesses seeking to thrive in today's competitive market.In conclusion, the Small 6 Axis Robot by [company name] represents a significant advancement in industrial automation. Its combination of advanced technology, compact design, and user-friendly interface makes it a standout choice for businesses across a wide range of industries. With its potential to streamline manufacturing processes and drive innovation, the Small 6 Axis Robot is set to make a lasting impact on the future of automation.

Exploring the Latest Developments and Advancements in Industrial Electric Motors

[Your Name][Date][--] Industrial Electric Motors Announces Groundbreaking Advancements in Electric Motor Technology[--], a global leader in industrial electric motors, is proud to introduce its latest innovations and technological advancements that are set to revolutionize the industry. With a rich history spanning over [--] years, [--] has consistently pushed the boundaries of what electric motors are capable of, and the company's latest developments are no exception. These advancements aim to enhance efficiency, increase durability, and reduce environmental impact, thereby providing customers with a cost-effective and sustainable solution for their industrial needs.One of the key highlights of [--] Industrial Electric Motors' latest breakthroughs is its cutting-edge design that allows for increased energy efficiency. By incorporating advanced electrical engineering, the motors are now able to convert electrical energy into mechanical energy with unprecedented accuracy. This results in a reduction in energy consumption, directly contributing to lower operating costs for businesses that rely on these motors for their operations.Additionally, [--] Industrial Electric Motors has taken great strides in ensuring their products' durability and longevity. The company's engineers have developed innovative techniques to improve the motors' resistance to wear and tear, thereby significantly extending their lifespan. This not only leads to reduced maintenance and replacement costs but also benefits the environment by minimizing waste generated from discarded motors.Moreover, [--] has recognized the importance of eco-friendliness in today's world and has been committed to developing sustainable solutions. The latest motors incorporate advanced materials and manufacturing processes that have a reduced carbon footprint compared to traditional motors. This demonstrates [--] Industrial Electric Motors' dedication to environmental responsibility while still maintaining high-performance standards.In addition to these advancements, [--] Industrial Electric Motors has also focused on enhancing safety features. Through comprehensive testing and analysis, the company has implemented improved safety protocols that ensure smooth and secure operation. These safety measures not only protect the machinery in which the motors are installed but also safeguard operators and reduce the risk of accidents or malfunctions.[--] Industrial Electric Motors understands that every industry has specific requirements, and as a result, the company offers a diverse range of motors to cater to various applications. From small-scale machinery to heavy-duty industrial equipment, [--] provides tailored solutions to meet the exact needs of its customers. This versatility, combined with its commitment to reliability and quality, has made [--] Industrial Electric Motors the preferred choice for businesses worldwide.With an extensive global distribution network, [--] Industrial Electric Motors is able to swiftly and efficiently deliver its products to customers across the globe. Furthermore, the company's exceptional after-sales service ensures that customers receive ongoing support and assistance, guaranteeing the optimal performance and longevity of the motors.As the industrial sector continues to evolve, [--] Industrial Electric Motors remains at the forefront of innovation, continuously striving to exceed industry standards and anticipate future needs. Through its groundbreaking advancements in electric motor technology, the company aims to empower businesses with efficient and sustainable solutions. By choosing [--] Industrial Electric Motors, customers can be confident in their investment, knowing that they are partnering with a trusted industry leader that prioritizes excellence and customer satisfaction.About [--] Industrial Electric Motors:Established in [--], [--] Industrial Electric Motors is a renowned global manufacturer of cutting-edge electric motors. With a rich history of technological innovation and a commitment to customer satisfaction, [--] has become a go-to solution for businesses across various industries. The company's versatile product portfolio, coupled with its dedication to energy efficiency and environmental responsibility, sets it apart from its competitors. Through its global distribution network and exceptional after-sales service, [--] ensures that customers receive the support they need to achieve optimal performance and longevity from its motors.For more information about [--] Industrial Electric Motors and its range of products, please visit [--] or contact [--] at [--].[Note: This text serves as a general template. Please modify and expand on the content to fit the specific brand and company details.]

Revolutionary Hydraulic Robot: An Innovating Breakthrough Redefining Automation Industry

Hydraulic Robot Technology Enhances Industrial Automation CapabilitiesIn recent years, industrial automation has become increasingly popular in various manufacturing industries. The industry’s fast-paced technological evolution has led to the creation of more advanced and sophisticated machines, capable of meeting the demands of a constantly-evolving marketplace.Hydraulic robots are one of the latest advancements in the field of industrial automation and have revolutionized manufacturing processes worldwide. The technology uses high-pressure fluids to generate power, which in turn drives the robot arm movement.A US-based company has recently introduced its latest hydraulic robot technology, which offers several key benefits to manufacturing industries. The technology is designed to support automation across countless industries, including automotive, aerospace, and military.This technology is capable of providing a variety of services and benefits to organizations. For starters, it can improve the overall efficiency of manufacturing processes by reducing the amount of time and resources spent on production. Additionally, this hybrid hydraulic robot can function more effectively alongside human workers, ensuring that both man and machine can work efficiently together to achieve optimal results.Hydraulic robot technology also offers the benefit of increased precision in manufacturing processes. With highly accurate robotic movements, companies can ensure consistent quality products while increasing the speed of production and reducing material waste. This level of precision is critical in the aerospace and military industries, where safety and reliability are of the utmost importance.The versatility of the technology also allows companies to use it for a wide range of tasks, including welding, painting, and assembly. This flexibility makes the technology a worthwhile investment for manufacturers looking to streamline their production processes and reduce costs.According to the company’s CEO, the hydraulic robot’s unique design is what sets it apart from other robotic technologies. Their product is designed with a focus on customization, with the ability to tailor the robot arm to the specific needs of individual projects. Furthermore, the use of high-pressure fluids allows the hydraulic robot to achieve a greater range of motion, pushing the limitations of conventional robotic technologies.At the core of all of its products is the company’s commitment to innovation. In an ever-evolving market, the company continues to pioneer new and advanced robotic technologies to give their clients the ability to transform their industrial processes and stay ahead of the competition.In conclusion, hydraulic robot technology has proved to be a game-changer in industrial automation, and its adoption by various industries is on the rise. Several companies worldwide have realized the immense benefits that hydraulic robots offer, including increased precision, flexibility, and efficiency. The technology’s versatility and customization capabilities make it a worthy investment for manufacturers looking to streamline their production processes and remain competitive in an ever-changing marketplace.

Ultimate Guide to Industrial Servo Drive Technology and Applications

Industrial Servo Drive is a key component in the automation and control systems of various industrial applications. It is a highly advanced and efficient solution that offers precise control and high performance for a wide range of industrial machinery and equipment.The Industrial Servo Drive market has been growing rapidly in recent years, as industries continue to embrace automation and smart manufacturing technologies. The demand for Industrial Servo Drives is being driven by the need for increased productivity, improved quality, and cost reduction in industrial processes.Industrial Servo Drives are widely used in industries such as automotive manufacturing, packaging, robotics, and material handling. They provide precise control of speed, torque, and position of the motor, which is essential for the proper functioning of the machinery in these industries. The high level of accuracy and performance offered by Industrial Servo Drives makes them a preferred choice for critical industrial applications.The key players in the Industrial Servo Drive market offer a wide range of products to meet the diverse needs of different industries. These products are designed to deliver high efficiency, flexibility, and reliability in demanding industrial environments. The Industrial Servo Drives are equipped with advanced features such as real-time monitoring, predictive maintenance, and self-diagnosis capabilities, which help in maximizing the uptime and productivity of the industrial machinery.One of the leading companies in the Industrial Servo Drive market is {}, a renowned manufacturer and supplier of industrial automation and control solutions. The company has a strong global presence and a solid reputation for delivering high-quality products and exceptional customer service.{} offers a comprehensive range of Industrial Servo Drives that are designed to meet the specific requirements of different industrial applications. The company's portfolio of Industrial Servo Drives includes compact and efficient models that are suitable for use in a variety of industrial machinery and equipment. These servo drives are known for their superior performance, precise control, and rugged construction, making them ideal for use in challenging industrial environments.One of the key advantages of {}'s Industrial Servo Drives is their advanced communication and networking capabilities. These servo drives are equipped with industry-standard communication interfaces, which enable seamless integration with different industrial control systems and automation platforms. This ensures easy interoperability and compatibility with other industrial equipment, allowing for greater flexibility and scalability in industrial automation solutions.In addition to high-performance products, {} also offers a range of value-added services to support their Industrial Servo Drives. The company provides comprehensive technical support, training, and consultancy services to help their customers effectively implement and optimize the use of Industrial Servo Drives in their industrial processes. This ensures that the customers can derive maximum value from their investment in {}'s products and achieve their operational goals.With the growing demand for Industrial Servo Drives in the global market, {} is committed to innovation and continuous improvement in their product offerings. The company invests heavily in research and development to introduce new features and technologies that address the evolving needs of the industrial automation industry. This allows {} to stay ahead of the competition and offer cutting-edge solutions that empower their customers to achieve higher levels of efficiency and productivity in their industrial operations.In conclusion, the Industrial Servo Drive market is witnessing significant growth and technological advancements, driven by the increasing adoption of automation and smart manufacturing solutions. Companies like {} are at the forefront of this market, offering high-performance Industrial Servo Drives and value-added services that cater to the diverse needs of industrial applications. With their strong commitment to innovation and customer satisfaction, {} is well-positioned to further expand its presence in the global Industrial Servo Drive market and continue to be a trusted partner for industrial automation and control solutions.

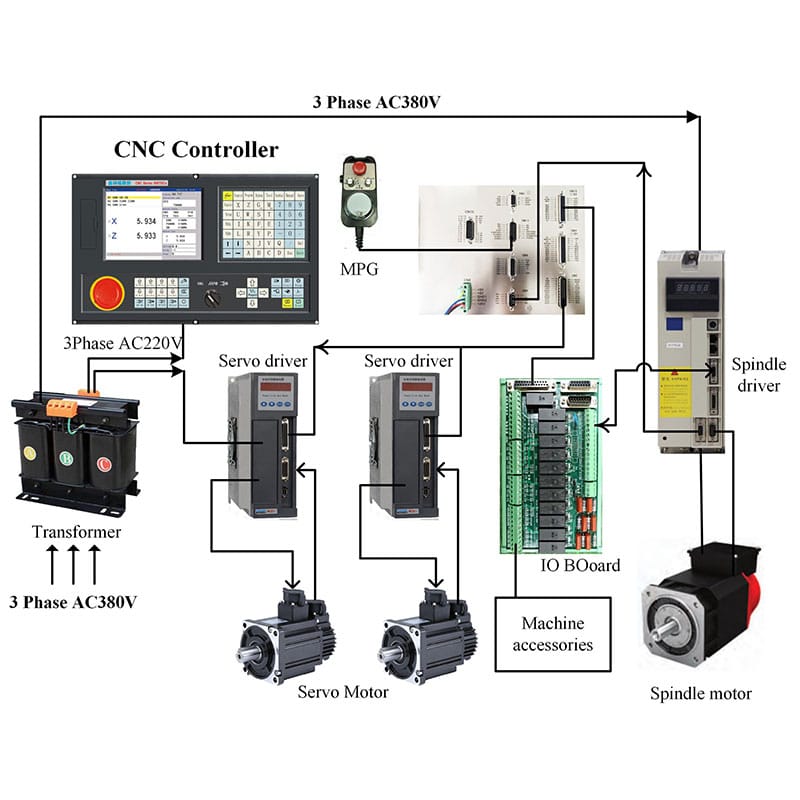

Advanced 6 Axis CNC Controller Technology: Latest Updates in Precision Machining Industry

6 Axis CNC Controller Revolutionizes Precision MachiningPrecision machining has always been a vital part of the manufacturing industry, allowing for the creation of complex and intricate parts with incredibly tight tolerances. One of the key components of any precision machining operation is the CNC (Computer Numerical Control) controller, which dictates the movement and operation of the machine tools. With advancements in technology, the latest 6 axis CNC controller from {} has revolutionized precision machining, providing unprecedented levels of accuracy, flexibility, and efficiency.{} is a leading provider of CNC controllers and automation solutions, with a rich history of innovation and a dedication to meeting the evolving needs of the manufacturing industry. The company's 6-axis CNC controller is the latest addition to their product lineup, and it promises to set a new standard for precision machining operations.The 6-axis CNC controller from {} features state-of-the-art technology that allows for the simultaneous control of up to 6 axes of motion, including linear and rotary axes. This level of flexibility opens up new possibilities for machining operations, allowing for the production of more complex and intricate parts. With the ability to control multiple axes simultaneously, the {} controller enables smoother, more efficient machining processes, reducing cycle times and improving overall productivity.In addition to its impressive performance capabilities, the {} 6-axis CNC controller also boasts advanced programming and customization options. The controller is equipped with a user-friendly interface that allows operators to easily program and customize their machining operations to suit their specific needs. This level of flexibility and control enables manufacturers to optimize their machining processes and achieve the highest levels of precision and accuracy.One of the key benefits of the {} 6-axis CNC controller is its ability to integrate seamlessly with a wide range of machine tools and equipment. Whether it's a milling machine, lathe, grinder, or any other type of machining equipment, the {} controller can be easily integrated to enhance its capabilities and performance. This level of compatibility and versatility makes the {} controller a valuable addition to any machining operation, allowing manufacturers to upgrade their existing equipment and unlock new levels of efficiency and productivity.The precision and accuracy offered by the {} 6-axis CNC controller are further enhanced by its advanced feedback and control systems. The controller is equipped with high-resolution encoders and feedback devices, allowing for precise monitoring and control of the machining process. This level of feedback and control ensures that every part produced with the {} controller meets the strictest quality standards, with tight tolerances and exceptional surface finishes.With the introduction of the 6-axis CNC controller, {} continues to demonstrate its commitment to pushing the boundaries of precision machining technology. By combining advanced technology, user-friendly programming, and seamless integration capabilities, the {} controller is poised to revolutionize precision machining operations across a wide range of industries.As manufacturing requirements continue to evolve, the need for more advanced and capable CNC controllers becomes increasingly important. The {} 6-axis CNC controller represents the next generation of precision machining technology, offering unprecedented levels of accuracy, flexibility, and efficiency. With its advanced capabilities and user-friendly interface, the {} controller is set to become an essential tool for manufacturers looking to stay ahead of the curve in the fast-paced world of precision machining.

Guide to Robot Arm Enemy in Strider NES Version

Robot Arm Claw – The Ultimate Pick-and-Place Machine for Industrial AutomationIn today's fast-paced world, businesses are constantly looking for solutions that can increase efficiency and productivity while simultaneously reducing costs. One area that is gaining significant attention in this regard is industrial automation. And at the heart of this revolution is the Robot Arm Claw – a device that is transforming the way industries operate.What exactly is a Robot Arm Claw?A Robot Arm Claw is essentially a robotic arm with a claw or gripper at the end. It is programmed to perform a variety of tasks that enable efficient and autonomous operation of industrial machinery. The arm's movements are controlled by a computer that is pre-programmed to carry out specific tasks, such as pick-and-place operations, assembly, and sorting.Benefits of Robot Arm ClawsRobot Arm Claws offer a host of benefits for businesses that use them in their day-to-day operations. Some of these are:1. Enhanced productivity: Robot Arm Claws can perform tasks 24/7 without any breaks or downtime. They work at a faster pace than humans, making them ideal for mass production environments.2. Increased precision: Robot Arm Claws can perform very precise tasks with an accuracy rate of up to 0.5mm. This level of precision makes them perfect for tasks that require extreme accuracy, such as high-tech assembly and testing.3. Improved safety: Robot Arm Claws eliminate the need for humans to perform dangerous tasks, reducing the risk of accidents in the workplace. This improves safety, reduces downtime, and lowers the liability exposure of the business.4. Reduced labor costs: Once programmed, Robot Arm Claws operate autonomously, reducing dependence on human labor and lowering overall labor costs.Applications of Robot Arm ClawsRobot Arm Claws are versatile machines that can be used in a wide range of industries, including manufacturing, food processing, packaging, chemical processing, and more. Some of the applications of Robot Arm Claws are:1. Pick-and-Place: Robot Arm Claws can be used to pick up objects at one location and place them at another. This makes them ideal for tasks such as sorting, palletizing, and packaging.2. Assembly: Robot Arm Claws can be used to assemble products with precision, making them ideal for industries that require high accuracy assembling.3. Inspection and testing: Robot Arm Claws can be used with cameras and sensors to inspect products and test them for quality control.The Future of Robot Arm ClawsThe future of Robot Arm Claws looks bright as industries continue to embrace industrial automation. The technology behind Robot Arm Claws is evolving, and new features are being added to make them even more efficient and versatile.In conclusion, Robot Arm Claws are transforming the industrial landscape, reducing costs, and enhancing productivity. They are ideal for businesses that require high precision, speed, and safety in their operations. As industries embrace automation, Robot Arm Claws are poised to play an even more significant role in the future of manufacturing and other industrial applications.

Understanding the Working Principle of Single Phase Induction Motors

Phase Induction Motor: The Future of Industrial ManufacturingAs the global manufacturing industry continues to advance and evolve, the demand for innovative and reliable machinery has become more crucial than ever. One company that has been at the forefront of providing cutting-edge solutions for industrial manufacturing is [company name]. With a strong focus on research and development, [company name] has recently unveiled their latest product - the 1 Phase Induction Motor, which is set to revolutionize the way industrial machinery operates.The 1 Phase Induction Motor is a testament to [company name]'s commitment to advancing technology in the manufacturing sector. Designed with precision engineering and state-of-the-art components, this motor delivers high-performance and efficiency, making it an ideal choice for a wide range of industrial applications. Whether it's powering conveyor belts, pumps, compressors, or other heavy-duty equipment, the 1 Phase Induction Motor is built to deliver consistent and reliable performance.One of the key features that sets the 1 Phase Induction Motor apart from its counterparts is its robust construction and durability. [company name] has utilized the latest materials and manufacturing techniques to ensure that the motor can withstand the rigors of industrial settings. This means reduced downtime and maintenance, ultimately leading to increased productivity and cost savings for businesses.In addition to its durability, the 1 Phase Induction Motor also boasts superior energy efficiency. With rising concerns about energy conservation and environmental sustainability, [company name] has integrated cutting-edge technology into the motor to minimize power consumption without compromising on performance. This not only benefits the environment but also helps businesses reduce their operating costs in the long run.Furthermore, the 1 Phase Induction Motor is designed for easy installation and integration into existing machinery. This plug-and-play feature allows businesses to seamlessly upgrade their equipment without the need for extensive reconfigurations, saving both time and money. The motor also comes with comprehensive technical support from [company name]'s team of experts, ensuring a smooth transition for businesses looking to adopt this innovative technology.The introduction of the 1 Phase Induction Motor reflects [company name]'s unwavering commitment to driving progress in the manufacturing industry. With a strong emphasis on research and development, the company has continuously pushed the boundaries of what is possible, consistently delivering innovative solutions that address the evolving needs of modern businesses.Founded with a vision to revolutionize industrial manufacturing, [company name] has established itself as a trusted partner for businesses seeking cutting-edge technology and reliable machinery. The company's extensive experience and expertise have allowed them to develop a broad portfolio of products that cater to various industrial applications, ranging from motors and drives to automation and control systems.Moreover, [company name] places a strong emphasis on quality and reliability, ensuring that every product that bears their name meets the highest standards of performance and durability. This commitment to excellence has earned [company name] a stellar reputation in the industry, making them the go-to choice for businesses looking to streamline their operations and maximize their productivity.Looking ahead, [company name] is poised to continue their legacy of innovation with the 1 Phase Induction Motor serving as a prime example of their dedication to driving progress in the manufacturing sector. As businesses around the world seek to optimize their operations and stay ahead of the competition, [company name] remains poised to provide the technology and solutions that will shape the future of industrial manufacturing.

Advanced 6 Axis Welding Robot for Precise and Efficient Welding

6 Axis Welding Robot Revolutionizes Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking ways to improve efficiency and production quality. The introduction of the 6 Axis Welding Robot from [Company Name] has been a game-changer in the industry, offering a new level of precision and automation to welding processes.With its six-axis articulation, the 6 Axis Welding Robot is capable of precise and complex movements, allowing for the creation of intricate welds with exceptional accuracy and repeatability. This level of precision is unprecedented in traditional manual welding processes, where human error and fatigue can often lead to inconsistencies in weld quality.[Company Name] has been a leader in the field of industrial automation for over a decade, consistently pushing the boundaries of technology to deliver innovative solutions to their customers. The introduction of the 6 Axis Welding Robot is a testament to their commitment to driving advancements in the manufacturing industry and empowering businesses to achieve higher levels of productivity and quality.The 6 Axis Welding Robot is equipped with advanced sensing and control systems, allowing for real-time monitoring and adjustments to ensure optimal weld quality. This level of automation reduces the need for human intervention in the welding process, freeing up skilled workers to focus on more complex tasks and increasing overall efficiency on the production floor.One of the key advantages of the 6 Axis Welding Robot is its ability to perform a wide range of welding applications, from simple spot welds to complex multi-pass welds on large workpieces. This versatility makes it an ideal solution for businesses with diverse welding needs, allowing them to streamline their operations and reduce the need for multiple specialized welding systems.Moreover, the 6 Axis Welding Robot has been designed with user-friendly programming and interface, making it accessible to both seasoned welding professionals and those new to automation. This ease of use empowers businesses to quickly integrate the robot into their existing processes and start seeing the benefits of improved weld quality and productivity.In addition to its technical capabilities, the 6 Axis Welding Robot is also designed with safety in mind. With built-in safety features and compliance with industry standards, [Company Name] ensures that businesses can trust in the reliability and security of their robotic systems, providing peace of mind in the workplace.The impact of the 6 Axis Welding Robot on the manufacturing industry has been significant, with many businesses reporting dramatic improvements in their welding processes and overall production efficiency. By leveraging the precision and automation of the robot, businesses have been able to reduce rework and scrap, achieve higher throughput, and ultimately deliver better quality products to their customers.Looking ahead, [Company Name] is committed to continuing their investment in research and development to further enhance the capabilities of their robotic systems, ensuring that businesses remain at the forefront of technological advancements in the manufacturing industry.As the manufacturing industry continues to evolve, the 6 Axis Welding Robot from [Company Name] has proven to be a transformative solution, empowering businesses to achieve higher levels of productivity, efficiency, and quality in their welding processes. With its unmatched precision, versatility, and ease of use, the robot has set a new standard for welding automation, driving a new era of innovation in manufacturing.

How to Handle a 4WD Robot Frame as a 2-Wheel Differential Drive: Tips from Robotics Experts

Bespoke Robotics Company Launches Groundbreaking 2-Wheel Drive RobotIntroducing a powerful yet easy-to-use robot that is guaranteed to revolutionize the world of robotics as we know it. Designed and developed by bespoke robotics company need remove brand name it has been aptly named 'The Baron' and is a magnificent creation that is capable of handling rough terrains with ease.The Baron is a 4WD robot frame which is unique in its design and handling. It has 4 static wheels, all driven by a motor which provides an excellent balance of power and control. However, the company has taken a new approach towards handling it. Rather than using it as a traditional 4-wheel drive, they have designed it to function as a 2-wheel differential drive.This means that the left and right wheels of The Baron would receive the same speed and direction while making turns. This makes the robot more maneuverable while also providing it with increased traction control. It can move in any direction with ease, making it the perfect tool for various applications.The Baron robot is equipped with a state-of-the-art control system that is simple and easy to use. The system is based on an open-source platform which provides immense flexibility and customizations. The control platform is user-friendly, allowing professionals and beginners alike to operate it with ease.The robot's drive is a closed-loop system that is accurate and responsive. It has been designed with the best possible motors and sensors to provide a seamless transition from manual to autonomous mode. The robot is equipped with different sensors like IR sensors, ultrasonic sensors, etc. which ensure that it can sense its environment and make accurate decisions based on the data.Need remove brand name is a bespoke robotics company that has been designing and manufacturing robotics solutions for over a decade. They have worked with various clients worldwide to provide them with customized robotics solutions that cater to their specific needs.Based on their vast experience and expertise, the company has developed The Baron robot, which is a perfect blend of innovation, technology, and performance. They have constructed it with the highest standards, using the best materials and components, ensuring longevity and durability.The Baron is designed for various applications, ranging from education, research, surveillance, exploration, and beyond. It is versatile and can be customized to cater to different applications, providing an excellent return on investment and a software platform for data acquisition and analysis.In conclusion, need remove brand name's Baron robot is a groundbreaking innovation that will transform the way we view robotics. The company's vision and expertise have culminated in a state-of-the-art robot that is perfect for various applications. If you're looking for a powerful and easy-to-use robot, you cannot go wrong with The Baron.