Understanding the Different Types of Servo Motors for Industrial Applications

By:Admin

One of the leading manufacturers of servo motors, {company name}, has been a key player in the industry for several decades. The company has a strong reputation for producing high-quality and reliable servo motors that meet the demanding requirements of modern industrial applications. {Company name} has a diverse product line of servo motors, including brushless DC motors, AC servo motors, and linear servo motors, catering to a wide range of applications and industries.

Brushless DC motors are known for their high efficiency, low maintenance, and precise control, making them ideal for applications that require high performance and reliability. {Company name}'s brushless DC motors are designed to deliver smooth and accurate motion control, making them suitable for robotics, precision positioning systems, and other high-tech applications. These motors are also known for their compact size, which makes them easy to integrate into various types of machinery.

AC servo motors are another key product in {company name}'s lineup, offering high torque and speed control for a wide range of industrial applications. These motors are widely used in CNC machines, industrial automation, and various other applications where precise control of motion is essential. With their advanced feedback systems and powerful control algorithms, {company name}'s AC servo motors are capable of delivering superior performance and reliability in demanding industrial environments.

Linear servo motors are a unique offering from {company name}, providing linear motion with high precision and dynamic performance. These motors are commonly used in applications such as pick-and-place systems, high-speed packaging equipment, and other machinery that requires precise linear motion control. {Company name}'s linear servo motors offer smooth and accurate motion, making them an ideal choice for applications that demand high precision and repeatability.

In addition to its diverse product line, {company name} is known for its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of servo motor technology, constantly striving to improve the performance, efficiency, and reliability of its products. {Company name} also offers comprehensive technical support and application engineering services, helping customers integrate its servo motors seamlessly into their machinery and achieve optimal performance.

Furthermore, {company name} has a global presence, with a strong network of sales and service locations around the world. This enables the company to provide timely support and solutions to its customers, regardless of their location or industry. With its extensive experience and expertise in servo motor technology, {company name} has established itself as a trusted partner for businesses in a wide range of industries, including manufacturing, robotics, automotive, and many others.

In conclusion, servo motors are a crucial component in modern industrial and commercial machinery, providing precise control and motion in a wide range of applications. {Company name} has been a key player in the servo motor industry for several decades, offering a diverse lineup of high-quality and reliable servo motors that meet the demanding requirements of modern industrial applications. With its commitment to innovation, technical expertise, and global presence, {company name} continues to be a leading provider of servo motor solutions for businesses around the world.

Company News & Blog

Wholesale Prices for Industrial Robots: A Look at the Cost of Automation Technology

Industrial Robot Wholesale Price Expected to Decrease in Response to Growing DemandAs the demand for industrial robots continues to grow, the wholesale price of these machines is expected to decrease in the near future. This trend is driven by several factors, including advancements in technology, increasing competition among robot manufacturers, and the continued adoption of automation in various industries.One company that is at the forefront of this trend is {Company Name}. Specializing in the development and production of industrial robots, {Company Name} has been a key player in the market for several years. With a strong focus on innovation and quality, the company has established itself as a leader in the robotics industry.{Company Name} offers a wide range of industrial robots, including robotic arms, automated guided vehicles (AGVs), and collaborative robots. These machines are designed to enhance efficiency, productivity, and safety in manufacturing and logistics operations. With a strong emphasis on user-friendly interfaces and advanced programming capabilities, {Company Name}'s robots are suitable for a variety of applications and industries.In addition to its product offerings, {Company Name} is known for its exceptional customer service and support. The company works closely with its clients to understand their specific needs and provide tailored solutions that meet their requirements. With a team of skilled engineers and technicians, {Company Name} is able to offer comprehensive training, maintenance, and troubleshooting services to ensure the smooth operation of its robots.Looking ahead, {Company Name} is optimistic about the future of the industrial robotics market. With the increasing demand for automation across different sectors, the company sees a significant opportunity for growth and expansion. By continuing to invest in research and development, as well as expanding its production capacities, {Company Name} aims to further solidify its position as a leading provider of industrial robots.In light of these developments, industry experts predict that the wholesale price of industrial robots is likely to decrease in the coming years. This is due to a combination of factors, including economies of scale, technological advancements, and heightened competition among robot manufacturers. As a result, businesses looking to invest in industrial automation can expect to benefit from more affordable robot options in the near future.The decreasing wholesale price of industrial robots is expected to have a positive impact on the overall adoption of automation in manufacturing and logistics. With lower upfront costs, more businesses may be inclined to integrate robotic solutions into their operations, leading to increased efficiency, reduced labor costs, and improved production capabilities.Moreover, the continued advancements in technology, such as machine learning, artificial intelligence, and sensor integration, are likely to make industrial robots even more versatile and capable. This will further enhance their value proposition for businesses looking to enhance their competitive edge through automation.As {Company Name} continues to innovate and expand its offerings, it is well-positioned to capitalize on these market trends. By leveraging its expertise and experience in industrial robotics, the company is poised to play a key role in driving the adoption of automation across different industries.In conclusion, the industrial robotics market is experiencing a period of significant growth and change. With the increasing demand for automation and the expected decrease in wholesale prices, businesses have an opportunity to leverage industrial robots for improved efficiency and productivity. Companies like {Company Name} are at the forefront of this trend, driving innovation and providing advanced robotic solutions to meet the evolving needs of the market.

Top Industrial Robot for Mobile Operations

Mobile Industrial Robot (MiR) has revolutionized the way logistics and manufacturing facilities operate with their innovative autonomous mobile robots. These robots have been designed to transport materials and goods efficiently and safely, significantly optimizing workflows in a wide range of industries.MiR’s robots are guided by advanced technology, including cameras, lasers, and sensors, allowing them to navigate dynamically changing environments with ease. With their ability to adapt to real-time obstacles and their user-friendly interface, MiR’s robots are a game-changer in the world of industrial automation.The company has rapidly gained recognition for its commitment to providing high-quality, reliable, and cost-effective automation solutions. With a strong focus on research and development, MiR continues to push the boundaries of what is possible in the field of autonomous mobile robots.One of the key factors that sets MiR apart from its competitors is their dedication to developing robots that are easy to install, program, and operate. This approach has made their robots accessible to a wide range of industries, from automotive and electronics manufacturing to pharmaceutical and food and beverage production.In addition to their user-friendly design, MiR’s robots are also renowned for their safety features. Equipped with advanced sensors and obstacle detection technology, these robots can navigate crowded and dynamic work environments while ensuring the safety of both human workers and the materials they transport.MiR’s robots are also designed to seamlessly integrate with existing warehouse management systems, allowing for a smooth and efficient transition to an automated logistics solution. This flexibility has made MiR a preferred choice for businesses looking to optimize their operations without disrupting their existing workflows.Recently, MiR announced the launch of their latest autonomous mobile robot, the MiR800. Building on the success of their previous models, the MiR800 is designed to handle heavier payloads of up to 800kg, making it suitable for a wider range of applications. With its advanced navigation capabilities and customizable payload options, the MiR800 is set to further expand the possibilities of automation in industrial settings.One of the key features of the MiR800 is its ability to autonomously pick up, transport, and deliver pallets, making it an invaluable tool for warehouse and distribution center operations. The robot is equipped with a user-friendly interface that allows for easy programming of routes and tasks, making it a valuable asset for businesses looking to streamline their intralogistics operations.The launch of the MiR800 comes at a time when businesses are increasingly turning to automation to improve efficiency and productivity. The robot’s ability to handle heavy payloads and navigate complex environments with ease positions it as a valuable asset for a wide range of industries, from automotive and aerospace manufacturing to e-commerce and retail distribution.In addition to the MiR800, MiR is also continuously improving its existing range of autonomous mobile robots, ensuring that they remain at the forefront of innovation in the industry. With a strong focus on customer feedback and technological advancements, MiR is committed to providing cutting-edge solutions that meet the evolving needs of modern businesses.As the demand for automation continues to grow, MiR is well-positioned to lead the way with their advanced autonomous mobile robots. Their commitment to user-friendly design, safety, and integration capabilities makes them a valuable partner for businesses looking to optimize their operations and stay ahead of the competition.In conclusion, Mobile Industrial Robot (MiR) has firmly established itself as a leader in the field of autonomous mobile robots. With their commitment to innovation, user-friendly design, and safety, they are driving the industry forward and helping businesses across the globe to achieve new levels of efficiency and productivity. With the launch of their latest robot, the MiR800, they are once again demonstrating their dedication to pushing the boundaries of what is possible in industrial automation.

High-Performance 4-Axis Stepper Driver for Precision Motion Control

A leading supplier of innovative motion control products, including 4 Axis Stepper Driver, has announced the launch of their latest product designed to provide precise control and superior performance in a compact and efficient package. The 4 Axis Stepper Driver is the newest addition to the company's extensive line of motion control solutions, and it is poised to revolutionize the way that businesses approach automation and robotics.The 4 Axis Stepper Driver offers a wide range of features and benefits that set it apart from other stepper drivers on the market. Featuring advanced microstepping technology, this driver is capable of delivering smooth and accurate motion control for a variety of applications, from 3D printing and CNC machining to robotic arm control and automated assembly lines. With a compact design and high power density, the 4 Axis Stepper Driver is an ideal choice for space-constrained installations where efficiency and performance are paramount.In addition to its advanced microstepping capabilities, the 4 Axis Stepper Driver also offers a number of user-friendly features that make it easy to integrate into new or existing motion control systems. With built-in protection circuitry and a user-friendly interface, this driver is designed to provide reliable and trouble-free operation in even the most demanding industrial environments. The driver also supports a wide range of input voltages and communication interfaces, making it compatible with a diverse array of control systems and industrial equipment.The development and release of this cutting-edge motion control solution is a testament to the company's commitment to innovation and excellence. With a proven track record of delivering high-quality products that are backed by industry-leading technical support and customer service, the company has established itself as a trusted partner for businesses seeking to optimize their motion control operations. By offering a comprehensive range of products and solutions, the company is able to address the unique needs of customers in a variety of industries, from manufacturing and packaging to aerospace and automotive.As a leader in the field of motion control, the company is dedicated to continuous improvement and ongoing research and development. This commitment to innovation has allowed the company to stay ahead of the curve and anticipate the evolving needs of the market. With a team of highly skilled engineers and technologists, the company is able to quickly adapt to new trends and technologies, ensuring that they are always at the forefront of the motion control industry.With the release of the 4 Axis Stepper Driver, the company is poised to further solidify its position as a leading provider of advanced motion control solutions. By leveraging their expertise and resources, the company is able to deliver products that not only meet the current demands of the market, but also anticipate and address potential future needs. This forward-thinking approach has earned the company a reputation for reliability, quality, and innovation, and it is this reputation that continues to attract customers from around the world.In conclusion, the release of the 4 Axis Stepper Driver represents a significant milestone for the company and the industry as a whole. With its advanced features, user-friendly design, and superior performance, this driver is set to become a game-changing solution for businesses seeking to optimize their motion control operations. As the company continues to push the boundaries of what is possible in motion control, customers can expect to benefit from a steady stream of cutting-edge products and solutions that are designed to meet their evolving needs.

Top 10 Remote Control Robots for a Futuristic Experience

Introducing the Next Generation: Remote Control RobotIn today's fast-paced and ever-changing world, technology continues to advance at an unprecedented rate. As industries strive to innovate and adapt to meet the demands of consumers, one company is at the forefront of this revolution. Introducing the cutting-edge Remote Control Robot from [Company Name], the next evolution of remote-controlled robotic technology.With a commitment to pushing the boundaries of what is possible, [Company Name] has developed a state-of-the-art Remote Control Robot that is set to revolutionize the way we interact with technology. This advanced robot combines the latest in robotics, artificial intelligence, and remote control technology to deliver an unparalleled experience for users of all ages.Equipped with a sleek and modern design, the Remote Control Robot is not only visually appealing but also packed with a wide range of features that make it a versatile and exciting addition to any tech enthusiast's collection. From its intuitive remote control system to its advanced sensors and cameras, this robot is designed to provide an immersive and interactive experience that is unlike anything else on the market.One of the key features of the Remote Control Robot is its advanced remote control system, which allows users to effortlessly navigate the robot with precision and ease. Whether you're using the included remote control or the companion smartphone app, controlling the robot has never been simpler. With a range of movement options and customizable controls, users can enjoy an intuitive and seamless experience that puts them in full control of the robot's actions.In addition to its remote control capabilities, the Remote Control Robot also boasts an array of advanced sensors and cameras that allow it to interact with its environment in incredible ways. With the ability to detect obstacles, recognize faces, and even respond to voice commands, this robot is as intelligent as it is powerful. Whether you're using it for entertainment, education, or exploration, the Remote Control Robot is sure to impress with its vast array of capabilities.Furthermore, the Remote Control Robot is designed to be fully customizable, allowing users to personalize their experience and tailor the robot to their specific needs and preferences. From adjusting its movement speed and agility to adding custom accessories and features, the possibilities are endless. This level of customization ensures that the robot can adapt to a wide range of use cases, making it suitable for everything from casual entertainment to professional applications.The Remote Control Robot from [Company Name] is not only a technological marvel but also a testament to the company's commitment to innovation and quality. With a focus on pushing the boundaries of what is possible, [Company Name] has created a robot that is on par with the latest advancements in robotics and artificial intelligence. By combining cutting-edge technology with a sleek and modern design, the Remote Control Robot represents the next generation of remote-controlled robotic devices.As technology continues to evolve and shape the world around us, the Remote Control Robot stands as a testament to the incredible possibilities that lie ahead. With its advanced features, intuitive controls, and unmatched versatility, this robot is set to redefine the way we interact with technology. Whether you're a tech enthusiast, a professional, or simply someone who appreciates the latest innovations, the Remote Control Robot from [Company Name] is sure to impress with its unmatched capabilities and endless potential.

New Welding Arm Robot Enhances Industrial Automation

A leading manufacturer in the robotics industry has recently launched a state-of-the-art Arm Robot For Weld, a cutting-edge robotic solution designed to improve welding processes in various industries. This advanced welding robot is set to revolutionize the way welding tasks are carried out, offering unprecedented precision, efficiency, and speed.The Arm Robot For Weld is equipped with the latest technology and is capable of performing a wide range of welding tasks with exceptional accuracy. Its advanced sensors and cameras allow for real-time monitoring and adjustments, ensuring that each weld is executed flawlessly. In addition, the robot is designed to work seamlessly with existing welding equipment, making it easy to integrate into manufacturing processes.This innovative welding robot is set to have a significant impact on industries such as automotive, aerospace, and manufacturing, where the demand for high-quality welds is crucial. By automating the welding process, companies can expect to see increased productivity, reduced labor costs, and improved overall quality of the final product.The company behind this groundbreaking Arm Robot For Weld has a long-standing reputation for delivering cutting-edge robotic solutions that are designed to meet the evolving needs of modern industrial processes. With a focus on innovation and excellence, the company has consistently pushed the boundaries of what is possible in the field of robotics, and this latest product is no exception.The Arm Robot For Weld is the result of years of research and development, and it represents the company's commitment to providing its customers with the best-in-class robotic solutions. By leveraging the latest advancements in technology, the company has managed to create a welding robot that is not only highly efficient but also easy to use and maintain.One of the key features of the Arm Robot For Weld is its versatility. Whether it's working on large-scale production lines or carrying out intricate welding tasks, this robot is up to the challenge. Its ability to adapt to different welding scenarios makes it an invaluable asset for companies looking to streamline their welding processes and improve overall efficiency.In addition to its impressive technical capabilities, the Arm Robot For Weld is also designed with user-friendliness in mind. Its intuitive interface and user-friendly controls make it easy for operators to program and monitor the robot, ensuring a smooth and seamless integration into existing manufacturing processes.Furthermore, the Arm Robot For Weld is equipped with advanced safety features, making it a reliable and secure solution for any welding environment. Its built-in collision detection and prevention systems ensure that the robot operates safely alongside human workers, minimizing the risk of accidents and injuries.The launch of the Arm Robot For Weld represents a significant milestone for the company, further solidifying its position as a leader in the robotics industry. With its cutting-edge technology, versatile capabilities, and uncompromising commitment to quality, this welding robot is set to make a lasting impact on the manufacturing landscape.As industries continue to evolve and demand higher levels of efficiency and productivity, innovative solutions such as the Arm Robot For Weld will play a crucial role in driving these advancements. By automating and optimizing the welding process, companies can expect to see tangible improvements in their operations, ultimately leading to a more competitive and sustainable future.In conclusion, the Arm Robot For Weld is a testament to the company's unwavering dedication to innovation and excellence. With its advanced technology, versatility, and user-friendly design, this welding robot is poised to set new standards in the industry and help companies achieve new levels of productivity and efficiency.

Efficient Multi Robot Control Systems for Enhanced Automation

Multi Robot Control Technology Revolutionizing the Manufacturing IndustryIn today's fast-paced and competitive world, manufacturers are constantly looking for ways to improve efficiency and reduce production costs. One of the most significant advancements in the manufacturing industry in recent years has been the development of multi-robot control technology. This technology allows multiple robots to work together seamlessly, improving productivity and flexibility in the manufacturing process.Company, a leader in the robotics and automation industry, has been at the forefront of developing and implementing multi-robot control technology. With a strong focus on innovation and cutting-edge technology, the company has revolutionized the way manufacturers approach automation and robotics.Multi-robot control technology allows for the coordination and synchronization of multiple robots working together on a common task. This technology enables manufacturers to achieve higher throughput, improved quality, and increased flexibility in their production processes. With the ability to program and control multiple robots from a single interface, manufacturers can streamline their operations and adapt to changing production demands more effectively.One of the key advantages of multi-robot control technology is its ability to optimize the use of available resources. By coordinating the movement and tasks of multiple robots, manufacturers can maximize the efficiency of their production lines and minimize idle time. This results in a significant increase in overall productivity and a reduction in production costs.The flexibility offered by multi-robot control technology is also a game-changer for manufacturers. With the ability to reconfigure and adapt the operation of multiple robots on the fly, manufacturers can quickly respond to changes in product design, production schedules, and customer demands. This level of adaptability is crucial in today's dynamic market environment and gives manufacturers a competitive edge.Furthermore, multi-robot control technology enhances the safety of manufacturing operations. By coordinating the movements of multiple robots, the risk of collisions and accidents is greatly reduced. The advanced algorithms and sensors used in multi-robot control systems ensure that robots can work together safely and efficiently, minimizing the potential for workplace incidents.Company has been instrumental in the successful implementation of multi-robot control technology in various manufacturing facilities across the globe. By collaborating closely with manufacturers, the company has been able to develop customized solutions that address specific production challenges and deliver tangible results.One of the key differentiators of Company's approach to multi-robot control technology is its focus on user-friendly interfaces and intuitive programming. This has made it easier for manufacturers to adopt and integrate multi-robot control technology into their existing production processes, without the need for extensive retraining or retooling.The impact of multi-robot control technology on the manufacturing industry has been profound. Manufacturers who have adopted this technology have seen significant improvements in productivity, quality, and flexibility, leading to a tangible competitive advantage in the market.Looking ahead, the future of multi-robot control technology is filled with promise. As advancements in robotics, artificial intelligence, and connectivity continue to evolve, the capabilities of multi-robot control technology will only become more sophisticated and powerful. This will open up new possibilities for manufacturers to further optimize their production processes and stay ahead of the curve in an increasingly competitive global market.In conclusion, multi-robot control technology has proven to be a game-changer for the manufacturing industry, and Company has been at the forefront of driving this revolution. With its focus on innovation, collaboration, and personalized solutions, the company is poised to continue leading the way in shaping the future of manufacturing through multi-robot control technology. As the industry continues to evolve, manufacturers will undoubtedly look to embrace this technology to stay ahead of the curve and achieve new levels of productivity and efficiency.

Revolutionary Programmable Servo Drive: Unleashing Next-Level Automation

Title: Revolutionary Programmable Servo Drive Set to Transform Automation IndustriesIntroduction:In today's rapidly evolving automation industries, staying ahead of the competition and optimizing production processes is crucial. Companies are constantly seeking innovative solutions to enhance efficiency, productivity, and overall performance. One such groundbreaking solution on the horizon is the latest Programmable Servo Drive.Revolutionizing Automation:The Programmable Servo Drive, developed by a leading technology firm, promises to revolutionize the automation industry. This cutting-edge product combines state-of-the-art technology with unparalleled performance, making it a game-changer for businesses across various sectors.Unparalleled Features:The Programmable Servo Drive boasts an array of features that make it stand out from its competitors. Its robust construction guarantees durability and ensures reliable operation. Equipped with advanced motion control algorithms, it ensures precise and smooth movement, significantly enhancing performance.Additionally, the Programmable Servo Drive offers scalable power capabilities, catering to diverse applications. Whether utilized in high-speed operation, heavy-duty machinery, or intricate assembly lines, this drive system adapts to any scenario, providing optimum results.Enhanced Efficiency and Precision:Automation experts predict that the Programmable Servo Drive will introduce a new era of efficiency and precision. Its intelligent control system enables seamless integration into existing automation infrastructure, minimizing installation time and cost.The drive's programmability allows for effortless customization and reconfiguration, making it adaptable to evolving production requirements. Flexibility is further amplified by its compatibility with various communication protocols, allowing for smooth integration with other automation components.Moreover, the servo drive's high-resolution feedback mechanism ensures precise positioning and control, reducing error rates and enhancing overall accuracy. By harnessing its advanced features, businesses can optimize operational efficiency, leading to increased productivity and reduced downtime.Industry Applications:The versatility of the Programmable Servo Drive renders it suitable for a wide range of industry applications. In manufacturing, it can be seamlessly integrated into robotics, machining centers, and assembly lines, enabling faster production cycles and superior quality control. Additionally, it finds utility in packaging, material handling, and food processing, where reliability and precision are paramount.Innovative Safety Features:Another notable aspect of this servo drive is its advanced safety features. Equipped with built-in condition monitoring capabilities, it enables predictive maintenance, preventing unexpected breakdowns and optimizing operational uptime. Integrated safety functions ensure a secure working environment, adhering to industry safety standards and regulations.Future Advancements:The development team behind the Programmable Servo Drive does not intend to rest on its laurels. They are committed to ongoing research and development, continuously exploring advancements in technology and identifying areas for improvement. Enhancements and updates will be deployed to ensure the drive system remains at the forefront of automation technology.Final Thoughts:The Programmable Servo Drive signifies a remarkable leap forward for the automation industry. With its combination of cutting-edge technology, advanced features, and exceptional performance, it promises to transform manufacturing processes across various sectors. By embracing this ground-breaking solution, businesses can achieve unparalleled efficiency, precision, and productivity, gaining a competitive edge in the dynamic world of automation.

High-performance Servo Motor Driver Module for Precision Control

Servo Motor Driver Module Enhances Company's Precision and EfficiencyIn today's fast-paced and competitive industrial landscape, manufacturing companies are constantly seeking innovative solutions to improve precision and efficiency in their production processes. One such solution that has garnered significant attention in recent times is the servo motor driver module. This advanced technology has the potential to revolutionize the way various industries operate, offering improved performance and accuracy in motion control applications.The servo motor driver module is a critical component in the operation of servo motors, which are widely used in industrial automation, robotics, CNC machining, and various other applications. These modules are designed to precisely control the movement of servo motors, providing the necessary power and speed to meet the specific requirements of a wide range of industrial processes.One company at the forefront of leveraging the potential of servo motor driver modules is [Company Name]. With a strong focus on innovation and technological advancement, [Company Name] has been successful in integrating servo motor driver modules into its manufacturing operations, resulting in enhanced precision and efficiency across its product lines.Established as a leading manufacturer in the industrial automation sector, [Company Name] has built a solid reputation for delivering high-quality and reliable automation solutions to its global clientele. The company's commitment to continuous improvement and technological innovation has been a key driver behind its decision to adopt servo motor driver modules in its operations.By incorporating servo motor driver modules into its manufacturing processes, [Company Name] has been able to achieve significant performance improvements in its motion control applications. The enhanced precision and speed control offered by these modules have allowed the company to meet the increasingly demanding requirements of its customers, while also optimizing its production processes for greater efficiency.Moreover, the adoption of servo motor driver modules has enabled [Company Name] to expand its capabilities in developing custom automation solutions for its clients. The flexibility and programmability of these modules have empowered the company to offer tailor-made automation systems that are specifically designed to meet the unique needs of different industries and applications.In addition to their superior performance, servo motor driver modules have also contributed to [Company Name]'s efforts in enhancing the safety and reliability of its automation systems. With advanced features such as fault detection and error monitoring, these modules have helped to minimize the risk of equipment failure and downtime, ensuring smooth and uninterrupted operation of the company's manufacturing facilities.Looking ahead, [Company Name] remains committed to further integrating servo motor driver modules into its operations, as part of its ongoing efforts to stay at the forefront of technological advancement in the industrial automation sector. The company recognizes the potential of this advanced technology in driving continuous improvement and innovation, and is keen on leveraging it to solidify its position as a leading provider of automation solutions in the global market.As the industrial landscape continues to evolve, the role of servo motor driver modules in enhancing precision and efficiency in manufacturing processes is set to become increasingly prominent. With [Company Name] leading the way in harnessing the potential of these modules, the company is well-positioned to deliver even greater value to its customers and stakeholders, while also contributing to the advancement of the industrial automation sector as a whole.

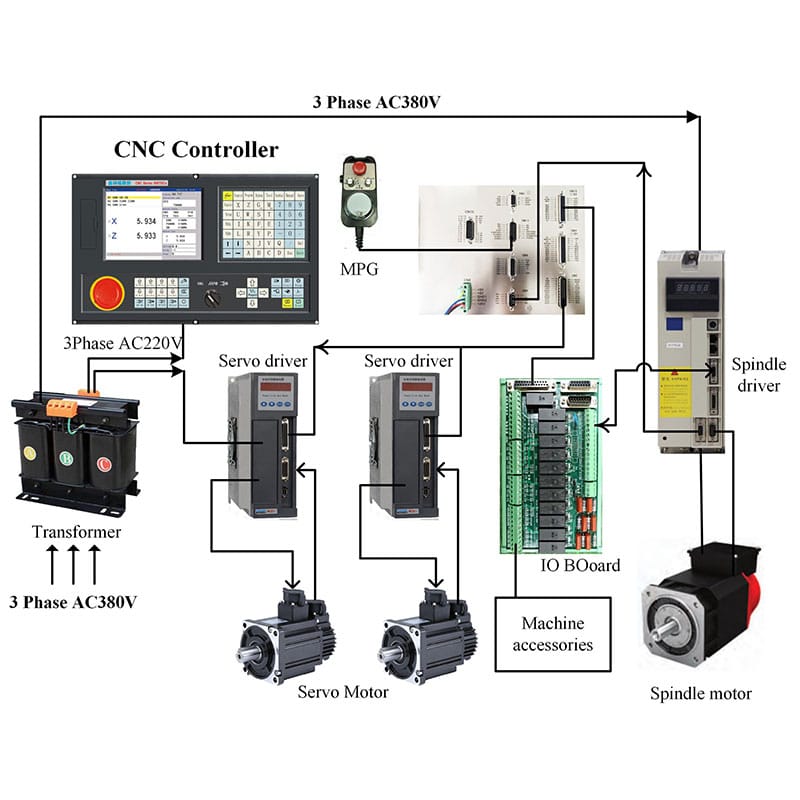

Advanced CNC Controller for Servo Systems: The Future of Precision Machining

Servo CNC Controller Offers Enhanced Precision and Performance for Manufacturing IndustryIn today's manufacturing industry, precision and performance are crucial elements for achieving high-quality production. With the ongoing advancements in technology, companies are constantly seeking innovative solutions to enhance their manufacturing processes. One such solution that has been making waves in the industry is the Servo CNC Controller, a cutting-edge system that offers superior precision and performance for a wide range of manufacturing applications.The Servo CNC Controller is a state-of-the-art control system that utilizes advanced servo motor technology to deliver highly accurate and efficient control of CNC machines. With its ability to precisely regulate the movement of machine tools and components, the Servo CNC Controller is capable of achieving intricate and complex machining operations with unparalleled precision. This level of precision is crucial for industries such as aerospace, automotive, and medical device manufacturing, where the smallest deviation in dimensions can result in significant quality issues.One of the key features of the Servo CNC Controller is its ability to adapt to various manufacturing processes, enabling it to accommodate the diverse needs of different industries and applications. Whether it's milling, turning, grinding, or any other machining operation, the Servo CNC Controller provides the flexibility and control necessary to optimize production processes and maintain high-quality standards.In addition to its precision, the Servo CNC Controller also offers enhanced performance capabilities that can significantly boost productivity in manufacturing operations. The advanced servo motor technology incorporated into the system allows for faster acceleration and deceleration of machine tools, resulting in shorter cycle times and increased efficiency. With the ability to rapidly execute machining operations without sacrificing precision, the Servo CNC Controller enables manufacturers to meet demanding production schedules and fulfill customer requirements with ease.Furthermore, the Servo CNC Controller is designed with user-friendly features that simplify the programming and operation of CNC machines. Its intuitive interface and advanced software allow operators to easily create and execute complex machining programs, reducing the time and effort required to set up and run production processes. This user-friendly design helps streamline manufacturing operations, making it easier for companies to adopt and integrate the Servo CNC Controller into their existing production systems.With its cutting-edge technology and versatile capabilities, the Servo CNC Controller has garnered widespread attention and acclaim from companies looking to elevate their manufacturing processes. From small-scale job shops to large-scale production facilities, businesses across the manufacturing sector are recognizing the potential of the Servo CNC Controller to enhance their competitiveness and drive growth.As a leading provider of advanced manufacturing solutions, [Company Name] has been at the forefront of introducing the Servo CNC Controller to the market. With a strong focus on innovation and customer satisfaction, [Company Name] has been instrumental in facilitating the adoption of this advanced control system across various industries. By leveraging their expertise and industry knowledge, [Company Name] has helped companies harness the power of the Servo CNC Controller to elevate their manufacturing capabilities and achieve superior results.In conclusion, the Servo CNC Controller represents a significant leap forward in the realm of manufacturing technology, offering unmatched precision and performance for a wide range of applications. Its adaptability, user-friendly design, and advanced capabilities make it a valuable asset for companies seeking to stay ahead in today's competitive manufacturing landscape. As technology continues to evolve, the Servo CNC Controller is poised to play a pivotal role in shaping the future of manufacturing, driving efficiency, productivity, and quality to new heights.

New servo motor improves machine speed and throughput in continuous duty applications

Rockwell Automation Introduces New Servo Motor for Enhanced Manufacturing EfficiencyRockwell Automation, a global leader in automation and digital transformation solutions, has introduced a new servo motor designed to enhance manufacturing efficiency. The latest addition to their product line, the high-performance servo motor, is known for its exceptional speed and torque capabilities.In today’s competitive manufacturing landscape, businesses are looking for new and innovative ways to boost product throughput and optimize their manufacturing operations. The Allen Bradley Kinetix VPC servo motor from Rockwell Automation is designed to address these challenges by delivering high-speed performance and high torque output.Manufacturers can now operate their machines at higher speeds without compromising on accuracy and precision, thanks to the improved speed and control capabilities of the new servo motor. The Kinetix VPC motor is capable of delivering up to 50% more torque and 20% more power as compared to traditional servo motors, making it an ideal choice for businesses looking to improve their continuous-duty applications.The servo motor, developed with advanced technologies to deliver enhanced speed, accuracy, and precision, is also equipped with advanced cooling mechanisms to ensure optimum performance in challenging environments. The motor's unique cooling system helps prevent overheating and extends the lifespan of the motors, making it an ideal solution for the most demanding applications.According to Tony Azure, Product Marketing Manager for Rockwell Automation, “The Kinetix VPC servo motor is built on the trust that the Allen Bradley brand has earned over the years for reliability and performance. With our Kinetix VPC servo motor, manufacturers can now achieve a significant reduction in machine downtime, improved throughput, and overall manufacturing efficiency”.The new servo motor is available in a range of sizes and configurations, making it a versatile solution for a variety of automation applications. The motor is also compatible with Rockwell Automation’s Integrated Architecture platform, making it easy to integrate with existing automation systems.Manufacturers can also leverage the Kinetix VPC servo motor to improve safety levels in their operations. Through its advanced control capabilities, the motor can detect and respond to changes in operating conditions, making it easier to prevent and address safety concerns on the shop floor.ConclusionOverall, the introduction of the Allen Bradley Kinetix VPC servo motor is set to revolutionize manufacturing operations, offering businesses a reliable and high-performing product for enhanced productivity. With features like high-speed operation, increased torque, and advanced cooling mechanisms, this latest servo motor from Rockwell Automation is on the frontline of delivering results for manufacturing companies, enabling them to produce more at a lower cost.