Advanced 7-Axis CNC Controller for Precision Machining

By:Admin

The manufacturing industry is constantly evolving, and companies are always on the lookout for state-of-the-art technology that can streamline production processes and improve overall efficiency. One such technological advancement that is making waves in the industry is the 7 Axis CNC Controller, a cutting-edge system that is redefining the way manufacturers approach their machining operations.

This game-changing CNC controller is designed to provide unparalleled precision and control over the machining process, allowing for the creation of complex and intricate parts with exceptional accuracy. By integrating advanced software and hardware components, this 7 Axis CNC Controller is capable of handling multiple axes simultaneously, pushing the boundaries of what is possible in the realm of precision manufacturing.

The capabilities of the 7 Axis CNC Controller are truly impressive, offering a level of flexibility and customization that was previously unheard of in the industry. This system can be seamlessly integrated into a wide range of machining equipment, from milling machines to lathes, providing manufacturers with the flexibility to adapt to various production requirements and specifications. With its advanced control algorithms and real-time monitoring features, the 7 Axis CNC Controller ensures that every machining operation is executed with the utmost precision and efficiency.

Furthermore, the user-friendly interface of the 7 Axis CNC Controller makes it easy for operators to program and control the machining process, minimizing the risk of errors and maximizing productivity. With intuitive software that allows for quick setup and adjustment of machining parameters, manufacturers can significantly reduce setup times and optimize their production workflows.

In addition to its technical capabilities, the 7 Axis CNC Controller is backed by extensive support and service from {}, a pioneering company in the field of CNC technology. Founded in {}, the company has established itself as a leading provider of innovative CNC solutions, with a strong focus on delivering cutting-edge technology that empowers manufacturers to achieve new levels of precision and performance.

With a deep understanding of the evolving needs of the manufacturing industry, {} is committed to pushing the boundaries of CNC technology and continuously developing advanced solutions that address the challenges faced by modern manufacturers. The 7 Axis CNC Controller is a testament to this commitment, representing the culmination of extensive research, development, and industry expertise.

As a trusted partner to manufacturers around the world, {} offers comprehensive training and support for the 7 Axis CNC Controller, ensuring that customers are able to fully leverage the capabilities of this groundbreaking technology. Backed by a team of experienced engineers and technical experts, the company is dedicated to providing end-to-end support to its customers, from installation and setup to ongoing maintenance and optimization.

The introduction of the 7 Axis CNC Controller is poised to transform the landscape of precision manufacturing, offering manufacturers a competitive edge by enabling them to produce high-quality, intricate parts with unparalleled efficiency and accuracy. As the industry continues to embrace digitalization and automation, the 7 Axis CNC Controller represents a significant leap forward in the evolution of manufacturing technology, paving the way for new possibilities in precision machining.

In conclusion, the 7 Axis CNC Controller is a game-changing technology that is revolutionizing the manufacturing industry, offering manufacturers a powerful solution for achieving new levels of precision and efficiency in their machining operations. With its advanced capabilities and comprehensive support from {}, this state-of-the-art CNC controller is poised to reshape the future of precision manufacturing and empower companies to stay ahead of the curve in an increasingly competitive market.

Company News & Blog

High Precision 3 Axis CNC Controller Kit with Servo Motors for Industrial Applications

We are excited to announce the launch of our new 3 Axis CNC Controller Kit Servo, which is set to revolutionize the CNC industry. This state-of-the-art controller kit is designed to provide users with a seamless and efficient CNC machining experience, offering unparalleled precision and control.At {company name}, we have always been committed to developing cutting-edge CNC solutions that meet the evolving needs of manufacturers and machinists. With our extensive experience and expertise in the industry, we have worked tirelessly to design a controller kit that exceeds the expectations of our customers.The 3 Axis CNC Controller Kit Servo is equipped with the latest technology to ensure optimal performance and reliability. Our team of engineers has incorporated advanced servo motors and drivers, along with a high-performance CNC controller, to deliver exceptional speed and accuracy. This means that users can expect smooth and precise machining operations, resulting in superior quality finished products.One of the key highlights of our controller kit is its user-friendly interface, which is designed to streamline the CNC machining process. The intuitive control panel allows users to easily program the machine, set parameters, and monitor the machining operations in real time. This not only saves time but also reduces the likelihood of errors, making it an ideal solution for both experienced and novice machinists.In addition, the 3 Axis CNC Controller Kit Servo is compatible with a wide range of CNC machines, making it a versatile and adaptable solution for various applications. Whether it's milling, turning, drilling, or engraving, our controller kit is designed to deliver consistent and reliable performance across different machining tasks.Furthermore, our controller kit is backed by comprehensive customer support and technical assistance. Our team is dedicated to providing prompt and effective assistance to ensure that our customers get the most out of their CNC machining operations. We understand the importance of minimizing downtime and maximizing productivity, which is why we are committed to offering top-notch support to our valued customers.In conclusion, the launch of our 3 Axis CNC Controller Kit Servo represents a significant milestone for {company name}. We are confident that this innovative solution will set new standards in the CNC industry, offering unmatched precision, reliability, and user-friendliness. With our commitment to excellence and customer satisfaction, we are excited to bring this controller kit to the market, and we look forward to the positive impact it will have on the machining operations of our customers.About {company name}:{company name} is a leading manufacturer and provider of CNC solutions, specializing in the development of advanced controller kits, motors, and accessories for CNC machines. With a focus on innovation and quality, we are dedicated to delivering cutting-edge solutions that empower manufacturers and machinists to achieve their production goals with efficiency and precision. Our team comprises experienced engineers and technicians who are passionate about developing reliable and user-friendly CNC products, backed by exceptional customer support and technical assistance.

Top-rated Energy-Efficient Motors: A Comprehensive Guide

Efficient Motors - Leading the Way in Energy-Efficient SolutionsIn today's rapidly changing world, the demand for energy-efficient solutions has never been greater. As concerns about climate change and environmental sustainability continue to grow, businesses and consumers alike are looking for ways to reduce their carbon footprint and minimize their impact on the planet. This is where Efficient Motors comes in. (Remove brand name), a leading provider of energy-efficient motors, is proud to be at the forefront of this important movement.Efficient Motors is a company that has been pioneering the development and production of energy-efficient motors for over 20 years. Through a combination of cutting-edge technology, innovative design, and a commitment to sustainability, the company has established itself as a global leader in the industry. With a diverse range of products and solutions, (remove brand name) continues to set the standard for energy efficiency and reliability in the motor industry."Our mission at Efficient Motors is to provide our customers with the most advanced and energy-efficient motor solutions available on the market," said (remove brand name), the CEO of the company. "We are dedicated to developing and producing motors that not only meet our customers' needs but also contribute to a more sustainable future for our planet."Efficient Motors offers a wide range of energy-efficient motors, including permanent magnet motors, synchronous reluctance motors, and high-efficiency induction motors. These products are designed to deliver the highest levels of performance while minimizing energy consumption and reducing environmental impact. By investing in the latest technology and manufacturing processes, (remove brand name) is able to produce motors that are not only efficient but also durable and reliable.One of the key factors that sets Efficient Motors apart from its competitors is its commitment to research and development. The company's dedicated team of engineers and designers are constantly working to develop new and innovative motor technologies that push the boundaries of energy efficiency. This focus on innovation has allowed (remove brand name) to stay ahead of the curve and continue to deliver state-of-the-art solutions to its customers.In addition to its cutting-edge products, Efficient Motors also places a strong emphasis on customer service and support. The company works closely with its clients to understand their specific needs and requirements, and then provides tailored solutions that help them achieve their energy efficiency goals. Whether it's a small-scale project or a large industrial application, (remove brand name) is committed to delivering the highest level of service and support to its customers.With a global presence and a reputation for excellence, Efficient Motors is well-positioned to lead the way in the energy-efficient motor industry. The company's products are used in a wide range of applications, including HVAC systems, industrial machinery, electric vehicles, and more. By providing efficient and reliable motor solutions, (remove brand name) is helping its customers reduce their energy consumption and operating costs, while also contributing to a cleaner and more sustainable planet.As the demand for energy-efficient solutions continues to grow, Efficient Motors is poised to play an even larger role in shaping the future of the motor industry. With its unwavering commitment to innovation, sustainability, and customer satisfaction, (remove brand name) is well-equipped to meet the evolving needs of its customers and contribute to a greener, more energy-efficient world.In conclusion, Efficient Motors is a company that is leading the way in energy-efficient motor solutions. With its advanced technology, innovative design, and commitment to sustainability, (remove brand name) continues to set the standard for excellence in the industry. As the demand for energy-efficient solutions continues to grow, Efficient Motors is well-positioned to play a significant role in shaping the future of the motor industry and contributing to a more sustainable planet.

Upgrade Your CNC Machine with a Retrofit for Improved Performance

CNC Retrofit: Upgrading Machinery for Enhanced PerformanceIn today's fast-paced manufacturing industry, companies are constantly looking for ways to improve productivity and efficiency. One of the most effective ways to achieve this is through the retrofitting of CNC (Computer Numerical Control) machinery. This process involves upgrading existing machinery with the latest technology to enhance its performance and functionality.With the rapid advancement of technology, older CNC machines can become outdated and struggle to keep up with the demands of modern production. This is where a CNC retrofit comes into play, offering a cost-effective solution for companies to breathe new life into their existing equipment. By upgrading the control system, motors, drives, and other key components, companies can improve accuracy, speed, and reliability, ultimately boosting their overall productivity.One company at the forefront of the CNC retrofit market is {}. With its extensive experience and expertise in the field of CNC machinery, {} has established itself as a leading provider of retrofit solutions for a wide range of industrial applications. The company's dedication to delivering high-quality products and services has earned it a reputation for excellence in the industry.{} offers a comprehensive range of retrofit services, catering to the specific needs of each customer. From initial consultation and assessment to the design and implementation of the retrofit solution, the company works closely with its clients to ensure the seamless integration of new technology into their existing machinery. By utilizing state-of-the-art components and cutting-edge software, {} can transform outdated CNC machines into highly efficient and reliable production assets.The benefits of a CNC retrofit are substantial. By upgrading the control system, operators can experience improved ease of use and functionality, leading to enhanced productivity and reduced downtime. Additionally, the integration of advanced software and hardware can result in greater precision and accuracy, ultimately leading to higher quality finished products. Furthermore, a retrofit can extend the lifespan of existing machinery, postponing the need for costly replacements and saving companies significant capital in the long run.In addition to the performance improvements, a CNC retrofit can also have a positive impact on environmental sustainability. By enhancing the efficiency of existing machinery, companies can reduce energy consumption and minimize waste, contributing to a greener and more sustainable manufacturing process.With the demand for CNC retrofit services on the rise, {} continues to innovate and expand its offerings to meet the evolving needs of the industry. The company's commitment to research and development ensures that its retrofit solutions remain at the forefront of technological advancement, delivering the highest level of performance and reliability to its customers.As the manufacturing landscape continues to evolve, the importance of investing in technology upgrades such as CNC retrofits cannot be overstated. With the expertise and support of companies like {}, manufacturers can optimize their existing machinery to meet the demands of today's competitive market, ensuring a sustainable and prosperous future for their operations.

High-powered 24v Electric Motor for Efficient Performance

A leading manufacturer in the electric motor industry has recently announced the release of their innovative 24v electric motor. This new product is designed to offer high performance and efficiency, catering to the growing demand for electric motors in various industries.With a focus on delivering cutting-edge technology and top-notch quality, the company has been at the forefront of the electric motor market for several years. Their commitment to research and development has enabled them to stay ahead of the competition and constantly introduce new, advanced products to the market.The 24v electric motor is a testament to the company's dedication to providing reliable and high-performing solutions for their customers. With a focus on performance, durability, and energy efficiency, this new motor is expected to make waves in the industry and meet the needs of a wide range of applications.One of the key features of the 24v electric motor is its compact design, which allows for easy integration into various systems and equipment. This makes it an ideal choice for manufacturers and businesses looking to enhance the performance of their products while reducing energy consumption.In addition to its compact size, the motor also boasts a high power output, making it suitable for demanding applications across different industries. Whether it's used in automotive, industrial, or commercial settings, this electric motor is designed to deliver consistent, reliable performance.The company's commitment to quality is evident in the rigorous testing and certification processes that all their products undergo. The 24v electric motor is no exception, as it has been thoroughly tested to ensure compliance with industry standards and regulations, giving customers peace of mind knowing they are investing in a high-quality, reliable product.Furthermore, the company's dedication to sustainability is reflected in the energy efficiency of the 24v electric motor. By minimizing energy consumption and reducing carbon emissions, this motor aligns with the company's environmentally conscious approach to manufacturing and product development.The release of the 24v electric motor comes at a time when industries are increasingly transitioning toward electrification and sustainable solutions. With the global push for reducing carbon footprints and embracing clean energy, electric motors have become a crucial component in various applications, ranging from electric vehicles to industrial machinery.The company's extensive experience and expertise in the electric motor industry positions them as a trusted partner for businesses seeking reliable, high-quality solutions. With a strong focus on customer satisfaction and continuous improvement, they are well-equipped to meet the diverse needs of their clients and provide tailored solutions to address specific challenges.As the demand for electric motors continues to grow, the introduction of the 24v electric motor further solidifies the company's position as an industry leader. With a proven track record of delivering top-of-the-line products and exceptional customer service, they are poised to make a significant impact with this latest addition to their product lineup.In conclusion, the release of the 24v electric motor underscores the company's commitment to innovation, quality, and sustainability. As industries continue to embrace electric solutions, this new motor is set to play a pivotal role in driving efficiency and performance across various applications. With its advanced features and high-performance capabilities, it is poised to set a new standard for electric motors in the industry.

Unlocking the Potential: The Power of Indexing Servo Drives Revealed!

Indexing Servo Drive, an innovative solution for precise motion control, is revolutionizing the industrial automation sector. Developed by a leading technology company, this advanced servo drive offers unparalleled performance, accuracy, and efficiency. With its cutting-edge features and capabilities, it has quickly gained prominence in various industries.The Indexing Servo Drive, developed by a highly reputed technological company, is a state-of-the-art solution designed to provide precise control over motion in industrial applications. This servo drive beats its competitors with its exceptional performance, reliability, and versatility. Its intelligent design allows for seamless integration into a wide range of manufacturing processes, making it an ideal choice for automation systems.The Indexing Servo Drive incorporates advanced technology, enabling it to deliver high-performance motion control. The servo drive offers extremely precise positioning, allowing for accurate movement and manipulation of machinery. Its superior speed and torque control capabilities ensure quick response times and efficient operation. This drive's ability to synchronize multiple axes enables precise coordination and synchronized motion, resulting in enhanced productivity and reduced downtime.With industry-leading features such as advanced feedback control, built-in safety functions, and real-time monitoring, the Indexing Servo Drive guarantees optimal performance and safety. The servo drive's closed-loop control system continuously monitors and adjusts various parameters to ensure accurate positioning and smooth operation. Its built-in safety functions include overcurrent protection, thermal overload protection, and error detection, safeguarding both equipment and operators from potential hazards.Furthermore, the Indexing Servo Drive's intelligent design reduces energy consumption and contributes to sustainable manufacturing practices. By optimizing power usage and reducing heat generation, this drive significantly lowers energy costs in industrial processes. Its regenerative braking capability converts excess energy into electrical power, further enhancing energy efficiency. With its eco-friendly features, this servo drive aligns with the company's commitment to environmental sustainability.The Indexing Servo Drive's user-friendly interface simplifies setup, configuration, and maintenance. Its intuitive software allows easy programming and parameterization, enabling quick adaptation to changing production requirements. The servo drive's comprehensive diagnostic capabilities facilitate efficient troubleshooting and predictive maintenance, optimizing operational efficiency and minimizing downtime.In addition to its exceptional performance and user-friendliness, this servo drive's robust construction ensures durability and reliability. Designed to withstand harsh industrial environments, it can endure extreme temperatures, vibrations, and shocks. Its long lifespan and minimal maintenance requirements contribute to a low total cost of ownership, making it a cost-effective solution for industrial automation.As a testament to its technological excellence, the Indexing Servo Drive has been widely adopted across various industries. It is successfully integrated into applications such as robotics, packaging, printing, and machining, providing precise and efficient motion control. The servo drive's versatility allows it to meet the unique requirements of different manufacturing processes, making it an indispensable tool for optimizing productivity and quality.In conclusion, the Indexing Servo Drive, developed by a pioneering technology company, is transforming the industrial automation landscape. This servo drive's exceptional performance, accuracy, and efficiency, coupled with its advanced features and user-friendly interface, make it an ideal choice for precise motion control. With its robust construction and reliability, it offers long-lasting performance for a wide range of industrial applications. Whether it's in robotics, packaging, or machining, the Indexing Servo Drive continues to deliver unmatched motion control capabilities, revolutionizing the way industries operate.

Enhancing CNC Performance with Adaptive Control System

The Adaptive Control System in CNC is revolutionizing the manufacturing industry by providing real-time monitoring and control of machining processes. This innovative technology, developed by [Company Name], is changing the way CNC machines operate, leading to higher efficiency, better quality products, and reduced production costs.[Company Name] is a leading provider of advanced manufacturing solutions, with a strong focus on CNC machinery. With years of experience and a team of dedicated engineers and researchers, the company has been at the forefront of developing cutting-edge technologies for the manufacturing industry. The Adaptive Control System in CNC is one of their latest breakthroughs and has already gained significant attention and recognition in the industry.The Adaptive Control System in CNC utilizes advanced algorithms and sensors to constantly monitor the machining process and make real-time adjustments to optimize performance. This level of control allows for more precise machining, resulting in higher quality products with tight tolerances. Additionally, the system can automatically adjust cutting speeds, feeds, and tool paths to minimize cycle times and maximize efficiency.One of the key features of the Adaptive Control System is its ability to adapt to changes in the machining environment. Whether it's variations in material properties, tool wear, or machine dynamics, the system can quickly adapt and make necessary adjustments to ensure consistent and reliable machining performance. This level of adaptability is particularly valuable in high-volume production environments, where even small improvements in efficiency can lead to significant cost savings.The benefits of the Adaptive Control System in CNC are not only limited to improved quality and efficiency but also extend to reducing downtime and maintenance costs. By constantly monitoring the machining process, the system can detect potential issues before they escalate into costly downtime, allowing for proactive maintenance and minimizing the risk of unexpected machine failures.Furthermore, the system's ability to optimize tool usage and reduce wear can extend the lifespan of cutting tools, leading to lower tooling costs and reduced tool changeovers. This is particularly valuable in industries such as aerospace and automotive, where high-performance cutting tools can be a significant expense.The Adaptive Control System in CNC has already been implemented in various manufacturing facilities with outstanding results. Companies that have adopted the technology have reported significant improvements in productivity, quality, and cost savings. With the ability to work with a wide range of CNC machines and applications, the system is versatile and can benefit manufacturers across various industries.[Company Name] is committed to further developing and refining the Adaptive Control System in CNC, with ongoing research and development efforts aimed at introducing even more advanced features and capabilities. The company's dedication to innovation and customer satisfaction has positioned them as a leader in the manufacturing technology industry.In conclusion, the Adaptive Control System in CNC developed by [Company Name] is a game-changer in the manufacturing industry. With its real-time monitoring, adaptive capabilities, and advanced control algorithms, the system is revolutionizing CNC machining and setting new standards for efficiency, quality, and cost-effectiveness. As the technology continues to evolve, manufacturers can expect even greater opportunities for improvement and innovation.

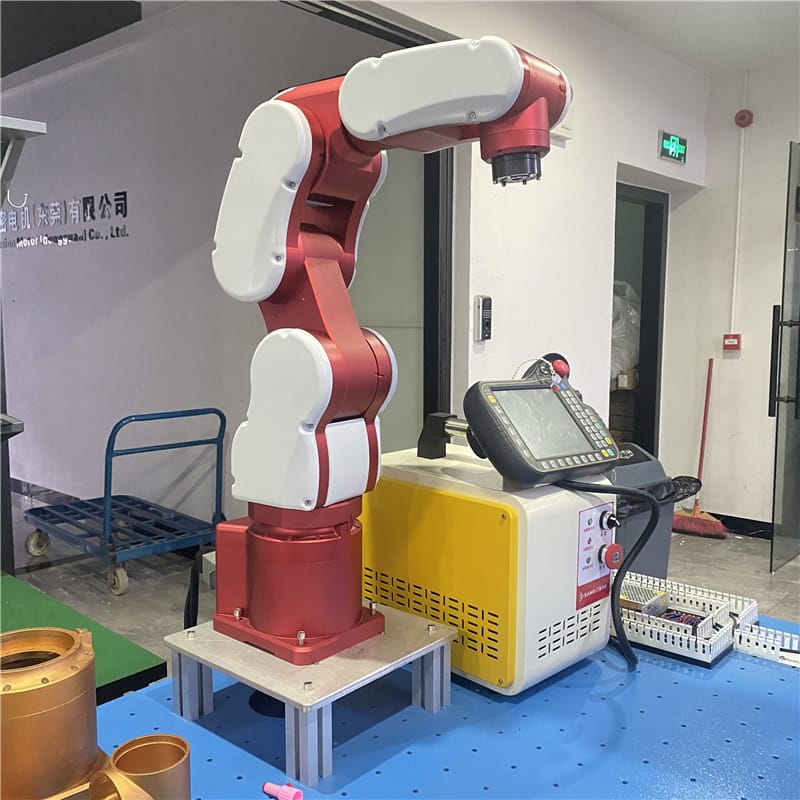

Advanced Pneumatic Robotic Arm Technology for Industrial Applications

Pneumatic Robotic Arm Revolutionizes Manufacturing IndustryThe manufacturing industry is constantly evolving with the incorporation of advanced technologies in production processes. In recent years, the integration of robotic arms has gained significant traction due to their ability to improve efficiency, precision, and overall productivity. One company at the forefront of this technological revolution is [Company Name], a leading provider of innovative automation solutions. With a strong focus on research and development, the company has recently introduced a game-changing product - the Pneumatic Robotic Arm. This cutting-edge technology has the potential to revolutionize the manufacturing industry by offering unparalleled performance and versatility.The Pneumatic Robotic Arm developed by [Company Name] is designed to meet the growing demand for advanced automation solutions in various industries such as automotive, electronics, aerospace, and more. The key feature of this robotic arm is its utilization of pneumatic power, which offers several advantages over traditional hydraulic or electric systems. Pneumatic technology is known for its high power-to-weight ratio, quick response times, and cost-effectiveness. These attributes make it an ideal choice for robotic applications where speed, precision, and reliability are crucial. By harnessing the power of pneumatic actuators, the Pneumatic Robotic Arm from [Company Name] delivers exceptional performance while minimizing energy consumption and reducing overall operating costs.Moreover, this innovative robotic arm is equipped with advanced sensors and control systems that enable it to perform a wide range of complex tasks with utmost accuracy. Its intuitive programming interface allows for seamless integration into existing production lines, making it a versatile solution for automating repetitive and labor-intensive processes. One of the key advantages of the Pneumatic Robotic Arm is its flexibility and adaptability. It is capable of handling diverse payloads and performing intricate manipulations, making it suitable for a wide variety of manufacturing applications. Whether it's assembly, packaging, material handling, or inspection, this robotic arm can significantly enhance operational efficiency and quality standards.Another noteworthy aspect of the Pneumatic Robotic Arm is its emphasis on safety and user-friendly design. With built-in safety features and compliance with industry standards, it ensures a secure working environment for operators and seamless integration into existing production facilities.[Company Name] is committed to providing comprehensive support and expertise to its customers, ensuring seamless implementation and maximizing the potential of the Pneumatic Robotic Arm in their operations. With a global network of service and support centers, the company offers unmatched technical assistance, training, and spare parts availability to ensure the continued success of its clients.In conclusion, the introduction of the Pneumatic Robotic Arm from [Company Name] represents a significant milestone in the evolution of automation technology. Its innovative design, advanced capabilities, and unparalleled performance are poised to transform the manufacturing industry by streamlining production processes, improving quality, and driving overall efficiency.This groundbreaking product exemplifies [Company Name]'s dedication to innovation and its commitment to delivering cutting-edge solutions that empower businesses to thrive in a rapidly evolving market. As the demand for advanced automation solutions continues to grow, the Pneumatic Robotic Arm is set to become a game-changer for manufacturers looking to stay ahead of the curve and achieve new levels of productivity and competitiveness.

Exploring the Power of Electric Motor Torque - Your Comprehensive Guide

[Company Name] Unveils Groundbreaking Electric Motor Torque Technology[date]In an era defined by rapid advancements in technology and the push for sustainable energy solutions, [Company Name] has emerged as a beacon of innovation. The company, renowned for its groundbreaking advancements in the field of electric motor torque, continues to push the boundaries of what is possible in the electric vehicle (EV) industry.Electric motor torque is a critical aspect of any electric vehicle, as it directly impacts the vehicle's performance, efficiency, and overall driving experience. [Company Name]'s cutting-edge electric motor torque technology has already garnered significant attention and is poised to revolutionize the EV market.Unlike traditional internal combustion engines, electric vehicles rely solely on electric motors to power their wheels. These electric motors generate torque, or rotational force, that propels the vehicle forward. Enhancing the efficiency and performance of electric motor torque directly translates into longer driving ranges and improved acceleration.With its unwavering commitment to innovation, [Company Name] has engineered a revolutionary electric motor torque system that surpasses industry standards. By optimizing motor design, leveraging advanced materials, and incorporating intelligent software algorithms, [Company Name] has achieved unprecedented levels of torque output and motor efficiency.The key to [Company Name]'s electric motor torque advantage lies in its groundbreaking motor design. Through meticulous engineering and years of research, the company has developed a highly compact and lightweight motor without compromising on performance. This breakthrough allows electric vehicles to benefit from enhanced agility and increased range, making them even more appealing to eco-conscious consumers.Furthermore, [Company Name]'s electric motor torque technology benefits from the use of cutting-edge materials. By utilizing lightweight but high-strength materials, such as carbon fiber composites, the company significantly reduces the overall weight of the motor. This reduction not only improves the vehicle's efficiency but also enhances its handling and maneuverability.In addition to its innovative design and material selection, [Company Name] has implemented intelligent software algorithms to optimize the performance of its electric motor torque system. These algorithms continuously analyze data from various sensors, such as wheel speed and power demand, to adjust the torque output in real-time. This dynamic control ensures both optimal performance and efficient energy consumption, ultimately extending the driving range of electric vehicles equipped with [Company Name]'s technology.The implications of [Company Name]'s electric motor torque advancements extend far beyond the automotive industry. With the increasing integration of EVs into various sectors, such as transportation, logistics, and even aerospace, the demand for high-performance electric motor torque systems has skyrocketed. By offering a compact, lightweight, and efficient solution, [Company Name] is poised to capitalize on this growing market and become a leader in the field.Moreover, [Company Name] aims to foster collaborations and partnerships to expedite the adoption of its electric motor torque technology. Through strategic alliances with major automakers and EV manufacturers, the company aims to integrate its cutting-edge torque systems into a wide range of electric vehicles, offering consumers an unprecedented driving experience.In conclusion, [Company Name] is revolutionizing the electric vehicle industry with its groundbreaking electric motor torque technology. By combining innovative motor design, advanced materials, and intelligent software algorithms, the company has pushed the boundaries of what is possible in terms of performance, efficiency, and driving experience. With the rising demand for sustainable transportation solutions, [Company Name]'s electric motor torque advancements position the company at the forefront of the EV revolution.

Discover the Latest Trends in Motor Control Panels

Motor Control Panel: A New Milestone in Electrical EngineeringIn the fast-paced world of electrical engineering, innovation is the key to success. With the demand for efficient and reliable electrical solutions on the rise, companies are constantly striving to push the boundaries of what is possible. One such company, [Company Name], is proud to announce the launch of their latest innovation in the field of motor control panels.Motor control panels are a critical component in various industries, from manufacturing and automation to oil and gas, and are essential for controlling the operation of electric motors. The new motor control panel from [Company Name] boasts cutting-edge technology and features that are designed to revolutionize the way businesses approach motor control.The motor control panel is equipped with state-of-the-art components and technologies, including advanced digital motor controllers, intelligent power monitoring, and seamless integration with industrial automation systems. These features not only ensure optimal performance and efficiency but also provide businesses with the flexibility and scalability they need to adapt to changing operational requirements.One of the key differentiators of [Company Name]'s motor control panel is its user-friendly interface and intuitive control system, which simplifies the monitoring and management of motor operations. This not only reduces the complexity of motor control but also minimizes the risk of human error, thereby enhancing safety and reliability.In addition to its advanced technical capabilities, the motor control panel is also designed with sustainability in mind. By incorporating energy-efficient components and intelligent power management features, [Company Name] is committed to helping businesses reduce their environmental impact and achieve energy savings.The development of the motor control panel is a testament to [Company Name]'s dedication to innovation and excellence in the field of electrical engineering. With a team of experienced engineers and technical experts, the company has a long-standing reputation for delivering high-quality electrical solutions that meet the evolving needs of their clients.Founded in [Year], [Company Name] has established itself as a trusted partner for businesses seeking reliable and innovative electrical products and solutions. With a focus on customer satisfaction and a commitment to delivering world-class products, the company has grown to become a leading player in the electrical engineering industry."We are excited to introduce our latest innovation, the motor control panel, to the market," said [Spokesperson Name], [Title] at [Company Name]. "We believe that this product represents a significant milestone in electrical engineering and will set new standards for motor control solutions. We are confident that our customers will benefit from the advanced capabilities and features that this product offers."With the launch of the motor control panel, [Company Name] is poised to further solidify its position as a leading provider of electrical solutions. The company's commitment to innovation and customer satisfaction continues to drive its success, and this latest offering is a testament to its dedication to pushing the boundaries of what is possible in electrical engineering.As businesses across various industries continue to rely on motor control panels for their operations, [Company Name]'s latest innovation is set to make a significant impact. With its advanced technology, user-friendly design, and focus on sustainability, the motor control panel is poised to become a preferred choice for businesses seeking reliable and efficient motor control solutions.In conclusion, the launch of [Company Name]'s motor control panel marks a new milestone in the field of electrical engineering. With its advanced technology, intuitive design, and focus on sustainability, this innovative product is set to redefine the way businesses approach motor control. As the company continues to lead the way in delivering cutting-edge electrical solutions, the motor control panel stands as a testament to [Company Name]'s commitment to excellence and innovation in the industry.

Innovative Mechanical Arm for Humans: A Breakthrough in Prosthetics Technology

In the ever-evolving field of technology and robotics, the use of mechanical arms for humans has become a revolutionary development. These advanced devices are designed to assist individuals with various needs, from physical disabilities to industrial applications. One company at the forefront of this innovation is [Company Name], a leading provider of cutting-edge robotic solutions.[Company Name] has been a pioneer in the development of mechanical arms for humans, with a focus on creating advanced and versatile devices that can be customized to meet the specific needs of users. Their expertise in robotics and engineering has enabled them to produce a range of high-quality, reliable, and efficient mechanical arms that are suitable for a wide range of applications.The [Company Name] mechanical arm is designed to provide users with enhanced dexterity, strength, and control, allowing them to perform a variety of tasks with precision and ease. Whether it's assisting individuals with limited mobility in their daily activities or enhancing the productivity of workers in industrial settings, these mechanical arms offer a significant improvement in functionality and quality of life.One of the key features of the [Company Name] mechanical arm is its advanced technology, which enables seamless integration with the user's natural movements and provides a high degree of flexibility and adaptability. This allows individuals to use the mechanical arm in a way that feels intuitive and natural, making it easier to perform tasks with precision and accuracy.Furthermore, the [Company Name] mechanical arm is equipped with state-of-the-art sensors and actuators, ensuring smooth and responsive movement. The device also features a lightweight and ergonomic design, making it comfortable to wear for extended periods without causing fatigue or discomfort.In addition to its focus on enhancing the lives of individuals, [Company Name] also caters to the needs of businesses and industries looking to improve efficiency and productivity. The company's mechanical arms are designed to meet the demands of various industries, from manufacturing and construction to healthcare and logistics.The use of mechanical arms in industrial settings can significantly enhance the capabilities of workers, allowing them to lift heavy objects, perform repetitive tasks with precision, and reduce the risk of workplace injuries. With the help of [Company Name]'s advanced robotic solutions, companies can streamline their operations, improve employee safety, and increase overall productivity.Furthermore, [Company Name] offers comprehensive support and customization options for their mechanical arms, ensuring that each device is tailored to the unique requirements of the user or application. Their team of experts works closely with clients to understand their specific needs and provide personalized solutions that deliver maximum value and performance.As a leader in the field of robotics and automation, [Company Name] is dedicated to pushing the boundaries of what is possible with mechanical arms for humans. Their commitment to innovation, quality, and customer satisfaction has earned them a reputation as a trusted and reliable provider of advanced robotic solutions.With an unwavering focus on excellence and a passion for pushing the limits of technological innovation, it's clear that [Company Name] will continue to play a pivotal role in shaping the future of mechanical arm technology. Whether it's empowering individuals with enhanced mobility and independence or helping businesses achieve new levels of efficiency and productivity, [Company Name]'s mechanical arms are set to make a significant impact on the world.